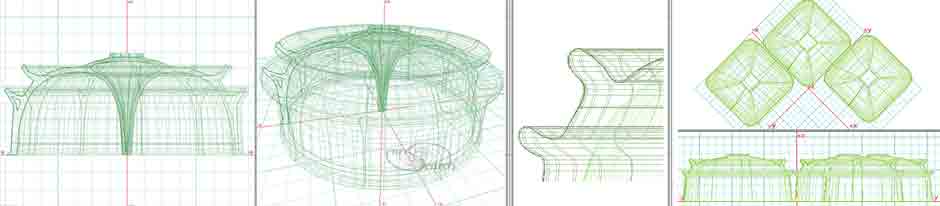

Circulating Barrel Vault: Simple Square & Round Shaped Examples

A Competitive Green Building Concept

A round-domed barrel vault can replace age old buttressing with an appropriate reinforcement ring. Yet a "horizontal buttress" contributes useful green-roof functionality, especially for the straight-walled barrel vault. The natural limitations of long, clear spans are mitigated with central pillars. A wide range of green construction materials may be used with small spans. Green materials are generally weaker than popular, manufactured materials. Larger clear spans require stronger, more expensively engineered treatment, than would use of half spans with central pillars.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

Balanced-tilt-up-construction for Circulating Vaults

It adapts to many possible floor plans from traditional to organic, singular units, multiple arrays or cloistered vaults.

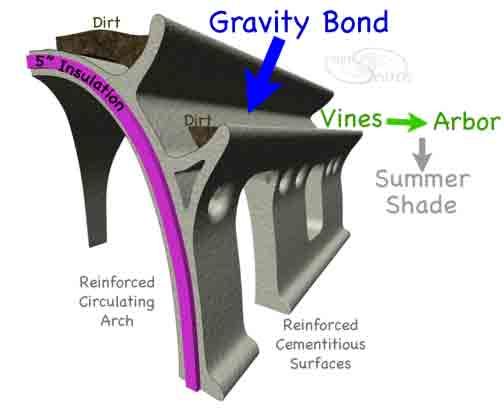

Green roof and living walls can be well supported by a concrete and insulation sandwich.

Sandwich construction is aided by gravity, both during the erection

phase and in ultimate structural bond.

Gravity bond eliminates heat loss of customary steel ties. Bond beams are monolithically & easily integrated.

Multiple, laminated

thin sheets of foam board or reflective bubble insulation can fit the curves.

Compressive arch achieved through a pivoting

or circulating vault geometry, (half-donut/bagel shape, yet with square

walls).

Arches allow more variety of green building materials

and methods, than would flat walls and flat ceilings.

Adapts to water and thermal storage to moderate heat

or cold, with insulation and strong materials.

Hanging garden arbor for ornamentals or vegetables provide shade in heat or allow sun through, in cold winters

Heavy or lightweight materials are adaptable, including recyclables and renewables, where feasible.

Competitive with

both low investment methods or highly invested (mechanized) methods of construction.

Greatly simplifies customized detailing, like planters and decor, through a

tilt-up advantage.

Lowest cost, conceptual tilt up through balanced tilting,

without expensive crane work. Heavy lifting to full height is partly self-lifted through balanced tilt-up!

Hereby, it is a highly energy efficient building process.

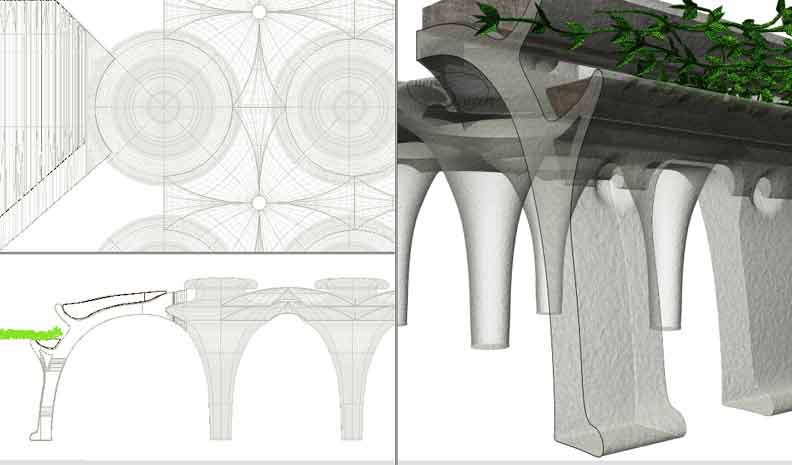

Multiple pillars can generally expand floor plans.

The example above adapts heavy should show that pillars can multitask. I love CAD modeling but almost always have priorities. Besides thermal moderation, many functional fixtures can be integrated within the pillars. Truly green construction would benefit with generous water storage cisterns held high for gravity flow. (More examples should be added here in future.) Much thinner pillar supports could otherwise work, where lightweight loads are preferred. Emphasis is on the widely flaring capitals on the pillar tops. Large capitols can morph into arches and vault work overhead. Hence an array of circulating barrel vaults on pillas. Also lacking in my CAD models here, is the consideration of frameworks, to strengthen interior surfaces. Perhaps some materials could pass strength tests, as drawn. Yet for average Portland mixes, i believe frame works or integral pilisters make sence. Otherwise coffers fashioned into shelf space or integral cabinets could also provide this sort of added reinforcement. Integrated building components make the most sence to me, but also require much more modeling time. I felt it worthy to present this simpler modeling, just to open a dialog on the subject. This type of structure also can be completely integrated with green HVAC.

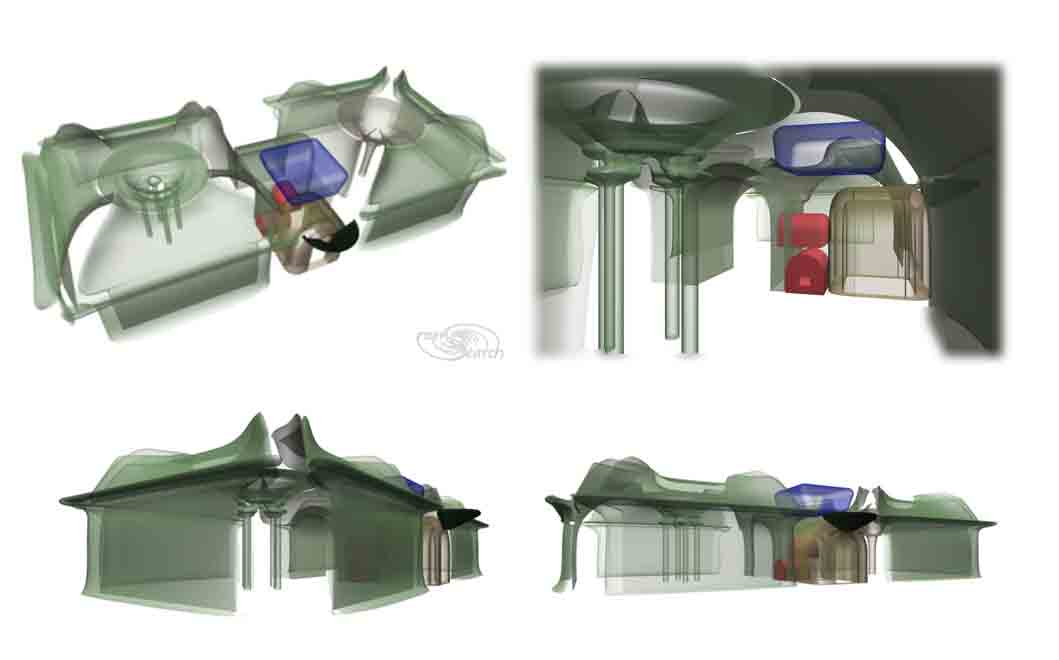

Completely un-buried Square Donuts could be adapted with customized arrangements of windows. Below is SquareDonut geometry optimized with true arcs (circles) at both center and along the diagonal joints. This provides both an interesting look and also a compressive-optimization along the mitered joints of the building. The bluish and reddish circles provide a verification of the true-arc geometry

Note that four columns are provided at center to somewhat reduce the longer diagonal span. Longer, clear spans would necessitate more expensive reinforcement. Therefore, shortening this span will effectively reduce the amount of reinforcement material needed to achieve the same amount of support. Next below is a model which integrates a wood-fired masonry-heater sandwiched between 2 square donuts. The idea here is to use solid concrete walls to hold refractory furnace components in an earthen aggregate. Also featured are sky lights at the mitered square donut joints. Such skylights would simplify the learning and exploration efforts.

Next

below is a version with a broad-flattened roof to provide a clear span. A

donut made large and flat would require a truss reinforced roof (in black).

The truss version looses the advantage of true arcs. True arcs provide the

economical ,compressive assets of arches. Straight trusses use more expensive

reinforcement materials, instead of arches. Yet construction methods and

sources can vastly over ride these bare facts.

Next

below is a version with a broad-flattened roof to provide a clear span. A

donut made large and flat would require a truss reinforced roof (in black).

The truss version looses the advantage of true arcs. True arcs provide the

economical ,compressive assets of arches. Straight trusses use more expensive

reinforcement materials, instead of arches. Yet construction methods and

sources can vastly over ride these bare facts.

Vaults made large and flat ,(clear spans), would require a more expensive truss reinforced roof (in black). Nevertheless, engineers have developed a variety of cost efficient approaches to build trusses as economically as possible. Welded steel mass produced units have less gain on the investment than could ferrocement or composite mass production. Structural strategy would make the difference. Truss installation will generally require use of cranes which also bear costs. One objective of this page is to avoid such costs. Here is another ferrocement or composite formed truss by the author for a recurve-cable-truss, based on ferrocement coiled-meshes. It may compete with other truss beams by using less material for the same performance. (Or provide more performance for the same cost).

The ancient compressive design-style tends to be heavier and bulkier but is generally fire safe without toxins. Compressive design in the modern era can better resist earthquakes by addition of frugal reinforcement strategies. Compressive design emulates monolithic structure and is commonly found in nature. Frugal "ferrocement" reinforcement has been proven in boats, over the decades. Today's plastics offer new, minimal reinforcement members, while cementitious technology almost approaches the strength levels of ductile metals! Industrial evolution offers increasing avenues to grow green structures. Despite these developments, agricultural building products also compete very well with fibrous reinforcements and insulation products. Forest products also promise competitive fibrous products while at the same time benefiting forests through sustainable punning practices. May we learn to nurture healthy growth and cut away bad parts of the design-vine.

Concerns have been raised about vault acoustics. Acoustics can be controlled by use acoustic materials or perhaps more interestingly with coffer structures. Coffer form work can be added to the circulating vault with an added bonus of inherent-reinforcement possible. Coffers are found to greatly minimize echo due to the physics of sound wave interference. Here is an example of organic coffers, a form of truss work copied from mother nature. Below are coffers in a 10M or 33ft dome under construction in the summer of 2006.

Another caveat suggested for earth sheltered structure is condensation. Unfortunately this issue lacks better and wider understanding. No doubt that a poor understanding of particular conditions can yield unwanted condensation, both in hot and cold climates. However this writer suggests that interior porosity of masonry can almost mitigate any surge of humidity as compared with highly sealed (painted) interior masonry. This suggests keeping the (important) vapor barrier just beneath the interior built-surface. Wooden floors however, should be sealed to protect from expansion and selected for proven humid-stability. If wooden floors are sealed and still provide good conduction downwards, the surfaces may indeed become wet during surges of humidity. In this case a dehumidifier which importantly preserves thermal needs and drains away humidity at the same time is called for. Such a dehumidifier can be integrated with a heat exchanger. Also including sky-light integration or earth-tube integration are both good possibilities, if suited to local climate.

(This writer also has learned the hard way, that chamfered wooden floor boards with noted swelling characteristics, really suffer under summer humidity surges. The chamfers especially ram the avid gardeners mud into the seam causing expansion problems still worse. The solution for this tripled problem was to literally saw off the chamfers in place with a circular saw).

Water coming vertically from below is a very rare occurrence and would be detectable as a spring. New water intrusion from neighboring sources must also be guarded against and solved before they become more expensive to solve. Water vapor does move upwards in the soil but that is likely more of a condensation cycle primarily due to radiant cooling at night along with humidity condensing on cooler soil during day (morning dew). Stored solar heat will reverse the direction of the ground condensation to a downward movement, (in cool weather). However, in hot climates, protection would need to reverse the effect by assuring a reliable water / vapor barrier. This is theoretical, but long pondered over, with personal observations as well. I have not seen scientific literature expound on this in layman terms, (but links would gladly be inserted here if received).

Arches & Pillars

The use of arches and pillars is advantageous where gravel and other supplies are plentiful. Each region favors particular material uses. In some cases, stony masonry or recycled brick might be advantageous. Recycled rubble from demolition debris might be appropriate for building with sticky concrete mixes. Reducing transportation costs will reduce building costs. Concrete can reduce flammability. Renewable bio-composites and selective admixtures can reduce planetary toxicity. High end, so called ductile composites (or Engineered Cementitious Composites, ECC), can reduce the total building mass. Whilst desirable thermal mass can be obtained from cisterns and the ground beneath. Reinforcement and insulation availability also varies according to geographic regions.The objective of this circular barrel vault module is to carefully integrate many efficient and desirable design criteria.

Regarding Manufactured Housing Also Called Prefab

I have responded to general inquiries which potential-entrepreneurs have emailed about. Aside from the many codes which builders must satisfy and how well mass-customized-building works and how specific technologies perform and how delivery /installation works... Optimized surface manufacture is the infrastructure. Research the optimum. The sandwich wall in-fill can vary widely. (At least as a goal to seek wider customized potentials while reducing transportation costs.) The insulating in-fill design should accept variable material input and thicknesses, (especially according to local codes and availabilities, also supply and demand. The US market has at least 10 climate zones worthy of at least 10 insulation customizations. Wet vs dry climates present further design criteria and more customization needs, on top of customizing essential stylization. Such customization should include comprehensive, multidisciplinary engineering.

Soil stabilization for building foundations should not be neglected. It is also more frequently reported that thermally integrating the foundation and the soil which surrounds a building will mitigate thermal extremes. (While reducing energy consumption and providing backup-thermal-comfort during a power outage or brown-out). This relates to Bucky Fullers amazing Synergetics implications for thermally integrating a whole city. Geothermal innovations through all times can be considered.

It is helpful to consider the many contexts of "testimonials" and contrasting applications long overlooked. Wikipedia has some developing key word links for our continuing self education: Wikipedia: Earth Sheltering Quote from Australia on underground living: "....It remains at a constant temperature, whereas surface living needs air-conditioning, especially during the summer months, when the temperature often exceed 40 degrees Celsius (100 degrees Fahrenheit). US residential builder's sites state: "home needs no heating or cooling".

Where dampness persists, insulation and reinforcement choices should not support mold growth. Foamed cement paste and foam pellet-aggregates, industrial fiber and agricultural fiber can all compete in particular regions. The housing market or a savvy researcher should develop a resource map. We should develop a chart to compare contributory strength of differing insulation infills and resilience's. A wide potential array exists, including mined, manufactured and recycled material. Thermal strategy and structural material can, in some lifestyles be integrated, as in the adobe architecture and other traditions as well.

Where windows mix regularly with small wall spaces between, loose, cheaper

insulation in-fill is just as good. This writer has lived happily

for several decades with dual 1.5" ferro-cement

walls held together only by wooden window and door framing (2X10

frames with loose vermiculite in my wall). Today, a composite can replace

wood

and

perhaps

nest compactly for

denser shipping. However, the "self heating or cooling house" presents

further issues than discussed here.

Rings Used For Reinforcing

This writer could be entirely wrong but does think ECC and other structural technologies will benefit considerably from "ring shaped fibers". Here is his original article published on the www. That is, were manufacturing made available. Simply change the geometric shape of the straight fiber into rounded rings. Note: ECC and Ductile specs do not mention tensile strength tests in terms of finished geometry variables, just flexural and compressive strengths of limited geometries. Tensile construction testing should include competitive geometries. Not that it is easy to design tests that are widely accepted. Yet a truer authority should continually update benchmarks which yield greater understanding. All such study is not far removed from reasonable concerns, not necessarily at least. Efficiency- interests are here to stay. Here to compete strongly. Here to demand harmony throughout all markets and all life. Here to demand public safety in a new paradigm which demands world peace, through truth, beauty and goodness, the greatest good for the the greatest number.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

![]()

Related Self Heating House Concept-Blogs.... (primarily for cold climates)

PAHS Retrofit - AGS For Ordinary Buildings

Square Donut Geometry - Disaster Resistant Structure

Branching U Tube Thermal Siphon For Perpetual Temperature Stabilization

Passive Annual Heat Storage Built Strong

Self Comforted House -- Ferrocementing for PAHS style building, Passive Haus, Passiv Jordvärme

2007 Informal Apprentice Workshop Offer, Click Here

Does a dome on top of a cylinder or box have or deserve a distinctive term? I see that the word "cloister" works for square and perhaps poly segmented dome-vaults. (Google Images show some.) Am I missing something more here? How about a non english term from any language? anyone?

A Turkish person wrote:It is, Mukarnas or Muqarnas. The root-word "karnas" is from Ural-Altaic language group and ancient Turkish, still speaking by Yakut Turks at Yakutsk region in siberia. "karnas" means = to(cause to)stand out....beyond an edge or surface.

The words bring up nice architectural pictures on Google Images: Mukarnas ...&... Muqarnas

In all technological and concept actualizations, appropriate consultation with registered and capable engineers before engaging in testing or building structures to observe codes and laws is recommended.

.