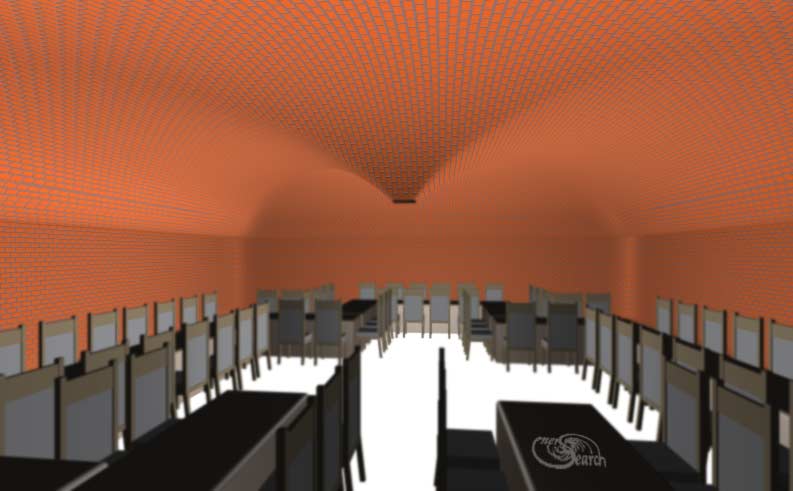

Dual brick arches supported in mid- air, what? Sometimes, visualization software does just what you want, (in this case formZ). Actually it is a brick donut vault supported at center by a suspension truss instead of a column. It is described below.

It is a proposed vault system combining dual compressive arches with a recurve truss system. Both arches meet at a bowed center. The arch ends rest on a bow sting suspension. (This articles assumes that comprehensive engineering would be carried out by licence professionals as a first step before any building would begin. The author only has formZ and artistic licence ;)

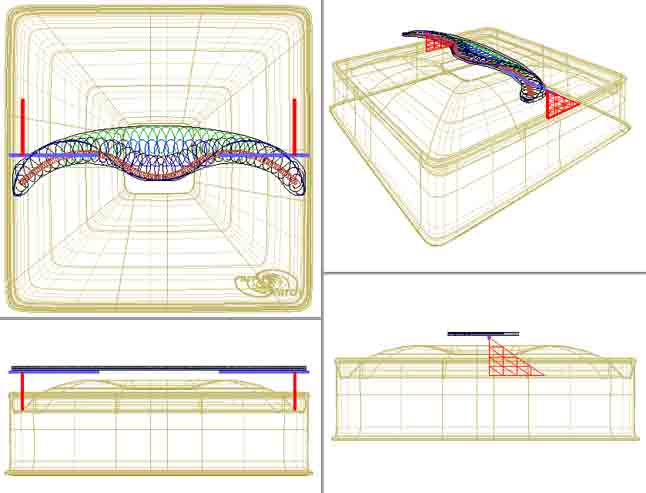

The concept above effectively doubles compressive arch spanning. A clear span, Mexican style Bobedero finish is rendered quickly in formZ. The visualization below depicts the recurve cable truss. This truss would be made with high tensile, flat coiled bars, wires or filaments. The flat coils would amply overlap. (Several variations appear on this website.) Colors are used to help distinguish the individual coils. The heavy black represents the largest coil. The red coil follows a "cable" path similar to a suspension bridge cable. This red recurve might be replaced by a simpler (set of) cable(s) or bar(s) as shown in some associated models. Ultimate specifications are the domain of engineers, (while the pages of this website are in the conceptual realm primarily). The other colors help distinguish the overlapping, continuous, coils. These coil or ring like reinforcements bind the entire truss together, after concrete or other cementitious composite consolidates the whole.

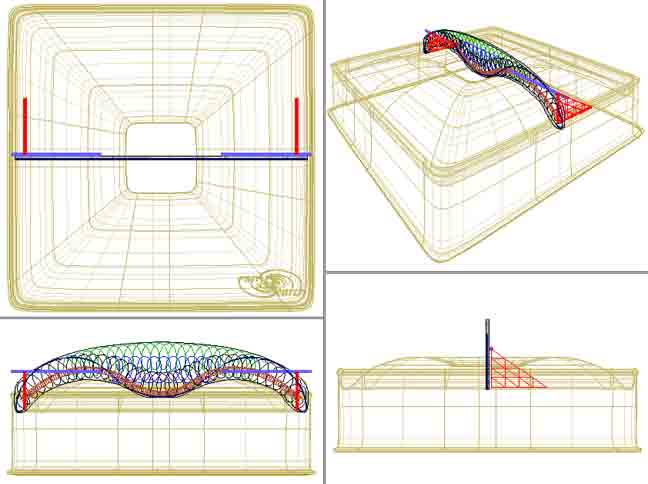

Innovative means are also considered to construct the truss and the vault. The vault parts could be formed with a balanced tiltup of quarter-sections, much as the manner described on this page. A temporary support would additionally be needed at center. Next the recurve truss would be formed on top, as illustrated below. A shaped form would be made first, (not shown). An axle (blue) would be provided to pivot upon the temporary (red) supports.The truss materials would be assembled on top. Coiled material is relatively easy to handel without needs to cut and place sharp edged meshes. Potentially, no welding or expensive joining would be needed. Fine tuned- overlapped positioning of coils has proven to be easy with simple weights or stays, to hold annular positioning. Then, these temporary stays are removed while cement is applied.

After the cementitious composite has developed adequate strength, the truss is ready to tilt into place. The tilting axle, as illustrated was placed at the centroid which allows economical tilting without expensive cranes. Much simpler winches, hoists, tackles or ropes can be employed. Appropriate ties would already protrude from the vault below. These would tie to truss at critical junctures. Next below is illustrated the truss after it is rotated or tilted up.

A thickness of 4 inches was drawn in the CAD model, which if made of concrete would weigh around 4 tons. Perhaps it could be found that a variable thickness will benefit the system. Much thinner, thickness might also be permitted, much depending on the material used. If we apply the greatest thickness near to the top of the truss, then it may do the most good as a compressive member. (Let the engineers and pioneers work this out).

No doubt crane owners may like to continue using there good equipment! Cranes do have an important place in the world. Therefore another approach to building modular trusses like this in a production facility. It has been illustrated on this link. Again, innovative technique is offered to extend the investment possibilities.

Helical Reinforcing (Flat Spirals)

This writer could be entirely wrong but does think ECC and other structural technologies will benefit considerably from "ring shaped fibers" and annular reinforcements generally. Here is his original article published on the www (link). If only manufacturing possibilities made available. Simply change the geometric shape of the straight reinforcement member into appropriately rounded shapes. Note: ECC and Ductile specs do not mention tensile strength tests in terms of finished geometry variables, just flexural and compressive strengths of limited geometries. Tensile construction testing should include competitive, fully-formed geometries. Not that it is easy to design tests that are widely accepted. Yet the truest authority should continually update benchmarks which yield greater understanding. All such study is not far removed from reasonable concerns, not necessarily at least. Efficiency- interests are here to stay. Here to compete strongly. Here to demand safety through an enlarging paradigm of harmony.

Other

pages in this series.  (Click

on blue writing to follow links.)

(Click

on blue writing to follow links.)

Self Heating House Concept-Blogs.... (primarily for cold climates, but may be explored for house cooling as well)

PAHS Retrofit - AGS For Ordinary Buildings

Square Donut Geometry - Disaster Resistant Structure

Branching U Tube Thermal Siphon For Perpetual Temperature Stabilization

Passive Annual Heat Storage Built Strong

Self Comforted House -- Ferrocementing for PAHS style building, Passive Haus, Passiv Jordvärme

Historical precursors before PAHS with a relevant discussion page....

Does a dome on top of a cylinder or box have or deserve a distinctive term? I see that the word "cloister" works for square and perhaps poly segmented dome-vaults. (Google Images show some.) Am I missing something more here? How about a non english term from any language? anyone?

A Turkish person wrote:It is, Mukarnas or Muqarnas. The root-word "karnas" is from Ural-Altaic language group and ancient Turkish, still speaking by Yakut Turks at Yakutsk region in siberia. "karnas" means = to(cause to)stand out....beyond an edge or surface.

The words bring up nice architectural pictures on Google Images: Mukarnas ...&... Muqarnas

2007 Informal Apprentice Workshop Offer, Click Here

Comments are invited and consultancy is offered. These research reports are in the public domain and are furnished "as is". The author makes no warranty, express or implied, for any purpose. The author assumes no responsibility for the use or misuse of this research. Bo Atkinson, enersearch Tel : 207 342 5796 . . . (MaineUSA)

E m a i l- boa1@pivot.net ___ Spam filters are in use, if your personal email doesn't get through, try calling: 1-207-342-5796. Unsolicited sales which are not directly related to discussion of this work are not welcome. Spammers: Get a life, try harmony!