This squared torus geometry offers the compressive assets of arches combined with square floor plans. It is a circulating barrel vault shape. Compressive efficiencies are conservational and can reduce wastes. It could be made of thick concrete, thinner ferro-cement, or other alternative building materials as well. Calibrated engineering could adapt it to withstand heavy loads of earth-covering, hurricanes, floods, earthquakes and disasters-generally. The square donut concept came in 2005, and was discussed on a ferrocement forum. It seemed that making a square unit with rounded surfaces would optimize the traditionally squared corner vault structure. Allowing that traditional building markets had lacked optimized strategies like ferro-cement. Unoptimized structures are generally adapted by everyone, including ferro cement enthusiasts. Geometric and practical optimization is the inspiration here.

Square-donut architecture offers strength and free form creativity for above ground buildings. Green roofs, (putting gardens on top of a roof) could also benefit from this high strength efficiency. Thermal mass has traditionally been enjoyed in partially buried buildings world wide but overlooked in modern times due to highly-marketed carbon fuels. A partly buried house structure benefits economically from annualized-geo-thermal storageS, (winter-heating and summer-cooling effects). HVAC with no monthly bills? The value of this concept has been over looked, largely due to excessive indulgence in oil with wasteful habits in society: Glib conservatism instead of disciplined conservation. Thin skin construction can use ferrocement or otherwise pioneer examples like basalt (rust proof, fire proof) reinforcement. ringforcement.

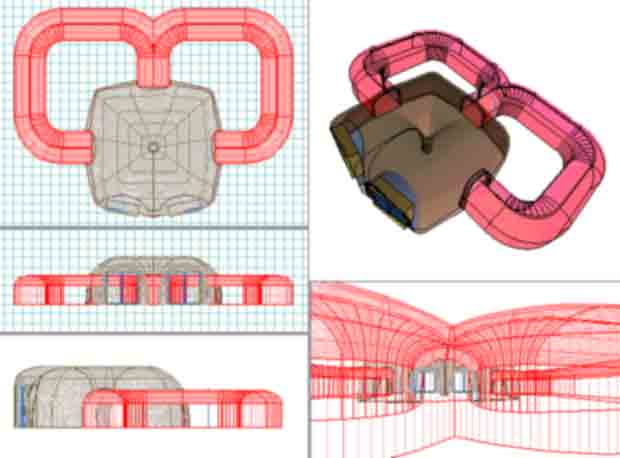

Completely un-buried Square Donuts could be adapted with customized arrangements of windows. Below is SquareDonut geometry optimized with true arcs (circles) at both center and along the diagonal joints. This provides both an interesting look and also a compressive-optimization. The bluish and reddish circles provide a verification of the true-arc geometry.

Note that four columns are provided at center to somewhat reduce the longer diagonal span. Longer, clear spans would necessitate more expensive reinforcement. Therefore, shortening this span will effectively reduce the amount of reinforcement material needed to achieve the same amount of support. Column support is more economical than using expensive, long-span-beams. Columns can be integrated.

Next below is a version with a broad-flattened roof to provide a longer clear span. Any ceiling or donut made large and flat would require considerable reinforced truss work(in black). The reinforcement- truss version looses the efficiency-advantage of true arcs. True arcs provide the economical ,compressive assets of arches for randomized dynamic stresses. Straight trusses use more expensive reinforcement materials, instead of cheaper compressively strong materials. Overly expensive method:

A hypothetically competitive building method, using a ready-mix concrete truck. Low Investment & High Productivity

Next below , a CAD model has wall thickness which is thickest midway between corners. The interior surface remains as in first picture while the outer surface bulges. The top exterior edge is shown thicker as in the Mexican barrel vault. The added bulk departs from pure ferrocement and might be more appropriate where bulkier material options are most economical.

The purely arced-arch evenly distributes strength along all points of a cross section. Arches don't have to be ideal arcs or ideal circles. However, this ideal is a geometric-resource for strength in all arches and any curvature generally. Cheap stone is a compressively strong building material and is exploited by arching across open spaces. An arching pillar is easier to use in place of the donut hole, making the whole structure compact. Since the mass production of steel, pure geometry in structure has been less exploited. But as the information age grows and oil declines, efficiency will again call on ideal elements of geometric pattern to solve many structural needs, micro, nano, macro and mega. Ring reinforcement is yet another option which exploits geometric patterns for reinforced structure.

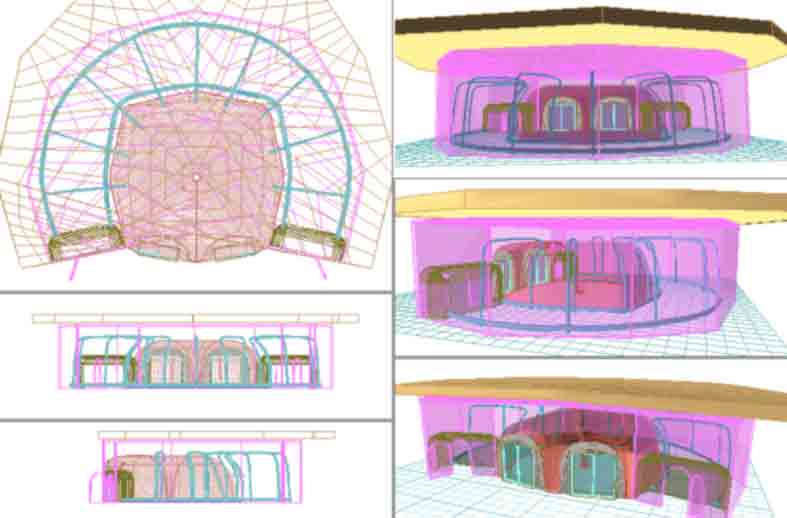

The model above is applicable for above ground and rammed earth adobe. Next below, the same structure is adapted with underground tunneling. Increased thermal exchange is the main objective along with additional storage space. Legacy- earthshelters dot com -Passive Annual Heat Storage was researched by a US Government Grant. An underground house was built and has reportedly been remarkably "self-heated" in the cold State of Montana for decades. Self-heating with nothing more than concrete architecture combined with geologic heat storage is a resilient concept.

Tunnels do add considerable cost but deserve cost-benefit analysis. The original breakthrough of Passive Annual Heat Storage adopted earth tubes to enhance thermal exchange, instead of tunnels. Concern about condensation with mold has dampened enthusiasm for inaccessible surfaces such as earth tubes. The tunnels provide accessibility to all thermal exchange surfaces. However, other means to enhance thermal exchange can be considered.

Next, below an exploratory example of unconnected earth tubes is offered. The pink surfaces are buried insulation which surrounds 3 sides and top of structure. Could this provide sufficient thermal exchange for cold climate house heating and cooling for the summer? (Thermal performance analysis is presently-in-2006, an expensive engineering service with utilizes expensive software.)

Next below is a more practical model than the version illustrated above. remove the bottom earth tubes, which are positioned radically and which are more labor intensive. They were replaced with larger collector earth tubes at bottom perimeter. This option reduces the amount of required excavation, in the event that the vertical insulation is used underground. More detail of this can be seen, (click here).

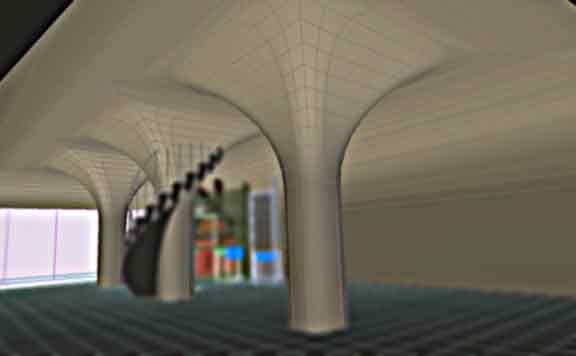

One further feature was added, namely two small rooms (brownish in color), which open to the outside. These small rooms may be used for nominal proposes, except that they are active parts of the heat storage system. All door and window should be mostly kept closed with this type of thermal strategy. Next below is a Square Donut vault doubled in length with three interior columns. Having columns, (made unusually massive on top), enhances thermal capacity and conduction.

Water cisterns could imaginatively fit in the upper portion of the column. Other functional fixtures could be built into the columns. Or arrangements of shelves, cabinets or partitions could altogether integrate within the columns. Below: a photo from the 1800s. Multiple functionality is suggested by these columns:

(Vatican Library Photo: From a collection by John Stoddard, C.1892). Thick columns splay out at the top. The square donut pillars adopt a similar pattern as traditional intersecting arches. The square donut approach smooths and rounds the seams between arches. Smoothed surface, material optimizing is the objective instead of sharp and hard corners of traditional masonry. Steel cross ties were added after the industrial age came, perhaps as an after thought, where modernization can optimize structure with internal reinforcement, updating from former masonry and former concrete without reinforcements.

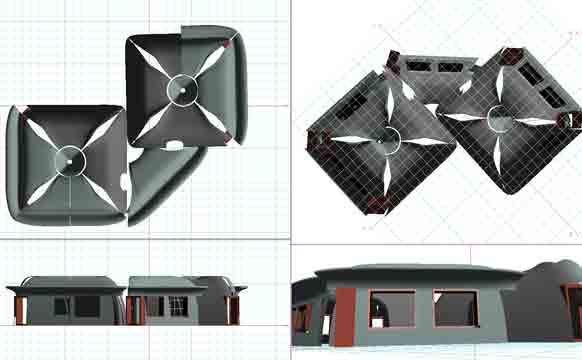

After discussing the advantages of adding a pillar, for a couple of years on the ferro cement forum... Mexico-Steve adapted his preferred forming system to an octagonal base. MxSteve might in fact be the world's first and only builder of a square donut structure! (My own effort was stopped when my client abandoned a 2007 project, involving my first square donut project. Such is life). However, the point of my page is to explore optimized surface geometry and meshes. Factory produced meshes bend easily in one direction only, (planar bending). Factory mesh does dominate markets. Trimming the mesh, or mangling it, can force fit a rounded donut surface (shape). These are non-optimal reinforcement patterns. Yet it is expedient to adapt familiar materials and crews, instead of starting to develop newer compound curve mesh systems. The traditional Mexican and Eurasian barrel vaults have used planar surfaces and do not form full circles or "donuts", nor significantly rounded corners. Perhaps fully rounded, circular vaults are found in India or Asia. Angularity persists in the west, where optimized geometry is overlooked in favor flat and angular structures. Mavericks endure derision and rarely get hired, but this provides time to contemplate optimizations. Steve Kornher and his Mexican maestros build remarkably beautiful vaults and other inspiring works in Mexico. The challenge of labor saving methods for building vaults gradually prompted the concept of tilting up four vault sections in sequence. As always, computer models with precise geometry gave confidence of getting proper clearances and devising efficient scaffolding.

Thanks to continued email from the the www-web, I was encouraged to try "test fits" and construction methods . Above: square donuts are tested in mixed configurations. The insertion of sky lights in the corner seams adds conservation of material while further ensuing a good fitting of parts.

A tilt up method for building this type of square donut structure.

Competitive Concepts For Efficient Structure "Green" (Globally Efficient)

Hypothetical Time saving approaches to building strong structure, calibrated by the amounts and configurations of reinforcements used. It is especially suitable for semi-buried or burmed buildings.

My latest on ring reinforcement theory and practice.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and assumes no responsibility for the improper use of the concepts, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

![]()

Edited 2025