Ferrocement

is an art form

of tension and compression, blending advantages of stone and metal

into imaginative, cost effective structure. (Structural

plastics and many other additives are also finding their way into artful

composites based on cements.) Here

are

some

pictures of what became imaginatively possible.

2009 2009

2009

2007

Above: one-man's labor with hindsight creativity providing solutions.

Menu

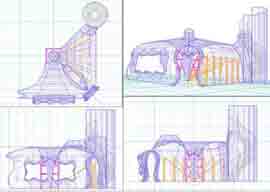

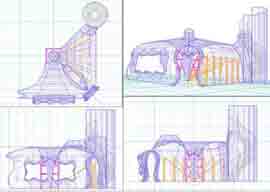

Dreamer's Geometry: Concave Catenary Subdivision of a Roof

Below: Roof

Garden Home With Hanging Garden Arbor Concept

Below:

CAD study for balanced- tilt-up construction.

Quick, "how to solve models" via

the www is offered freely as a public service, where possible, just ask!

(As time permits). Reasonable rates for highly customized, computer-accurate, 3D modeling. High resolution graphics and plans made to order.

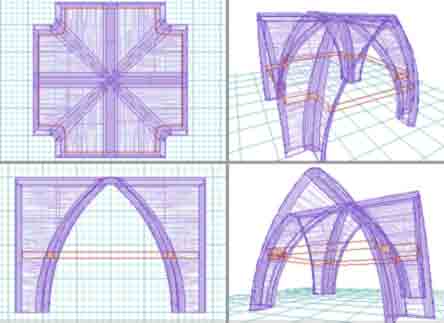

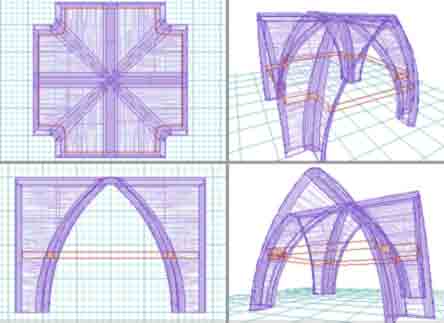

Below: A Gothic X Arches (For better or worse called a Groin Vault.)

Updates are occasionally

added to this website.

An automated dream

building method.

Using software as form work for concrete.

Camera Lucida: This

secret of the masters should work beautifully for sculptural concrete and

ferrocement.

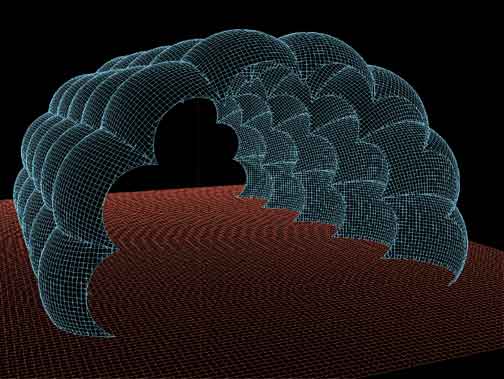

While scalloping uses more surface

area, it also engenders a framing component. Shells are reinforced by the

surface

corrugation. More surface can mean more labor and material, but it does offer

some strength advantages. Our world is improving tools to simplify curvilinear

construction. It remains for individuals to support those efforts and "vote

with the pocket book". The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

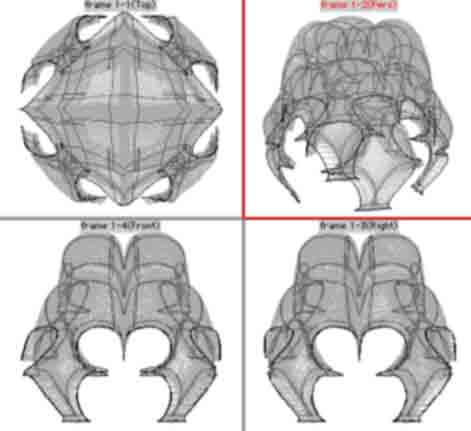

Here is a vault frame which can be

made of reinforced concrete rings as framework. Clickhere for related idea.

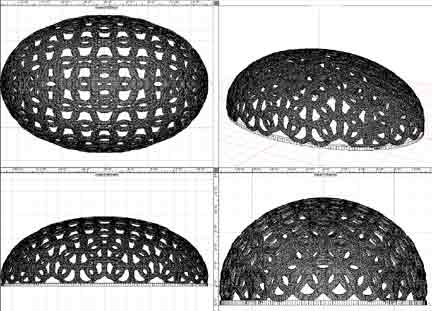

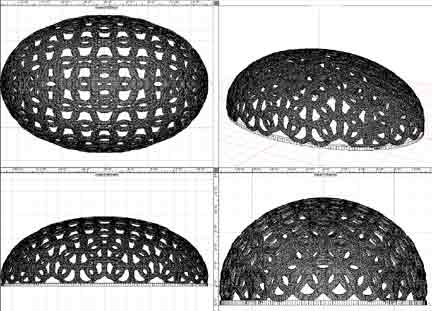

A

geodesic

star pattern grid work which beautifully adapts to a dome form.Click here

for other arch/ vault models.

Several more examples in this series

follow below...

Here is a vault frame which can be

made of reinforced concrete rings as framework. Clickhere for related idea.

A

geodesic

star pattern grid work which beautifully adapts to a dome form.Click here

for other arch/ vault models.

Several more examples in this series

follow below...

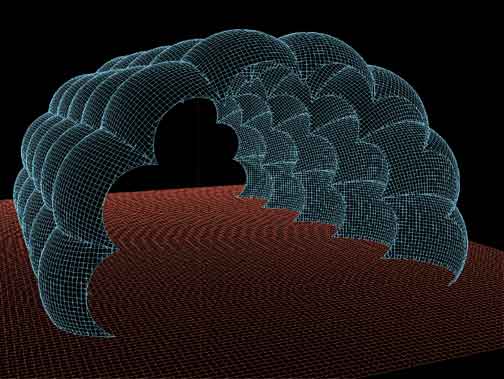

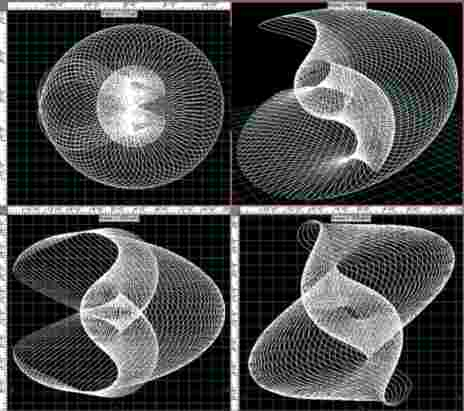

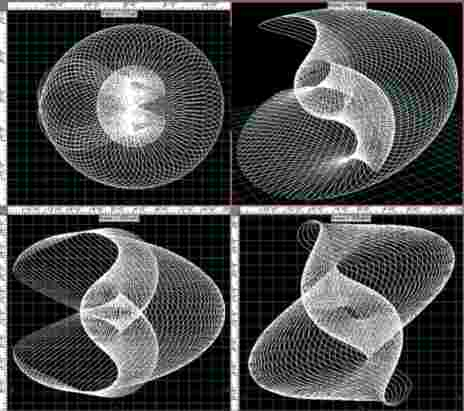

Next (above), is a sea shell like

cage design possibility. CAD, (design software) allows sculptors to access a

wide array of geometrical tools to determine difficult reinforcement configurations

and to develop methods for actual construction. Here is a link to ring reinforcement

as a means to build highly curved structures. Although reinforcement rings are

not easily- commercially available, a

"one man" approach to study feasibility of rings is under way,

slow but sure. Follow links on this website for much more on ring reinforcement

and on single person methods for construction, (where hired labor cannot be

afforded).

Next (above), is a sea shell like

cage design possibility. CAD, (design software) allows sculptors to access a

wide array of geometrical tools to determine difficult reinforcement configurations

and to develop methods for actual construction. Here is a link to ring reinforcement

as a means to build highly curved structures. Although reinforcement rings are

not easily- commercially available, a

"one man" approach to study feasibility of rings is under way,

slow but sure. Follow links on this website for much more on ring reinforcement

and on single person methods for construction, (where hired labor cannot be

afforded).

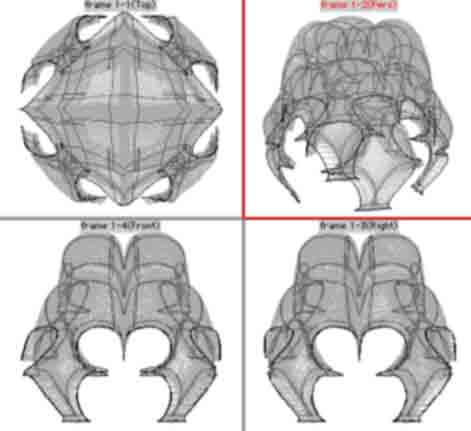

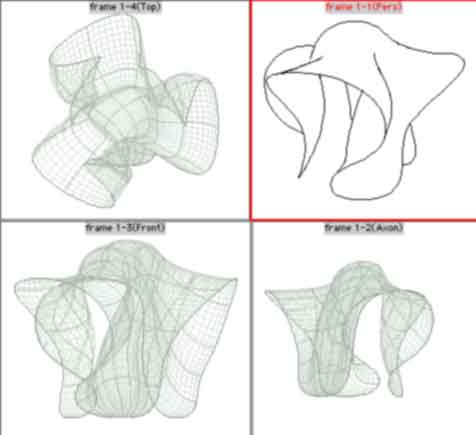

Next above is my effort with new software

tools to explore curved geometry. More

can be seen, click here.

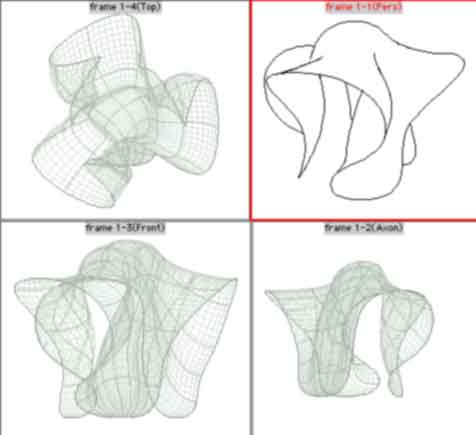

In this purely hypothetical CAD model

each arch has most surfaces at 1" thick with a gusset extending along the

whole curved portion of arch, (itself 1" thick). All large surfaces have

a slight ribbing to add strength at joining edges. The main span is 20 ft.

Total

wall/roof volume of each is about 9 cu ft., so wt is about 1170 lbs. If the

straight wall sections are separated and poured flat on the ground, and also

if the curved parts are poured on a sand pile/ mold... and all these are poured

in one or two sessions, then ready mix might be used. Sand casting methods

from

ancient tech apply. A backhoe could be used to lift all pieces into place,

(if safely managed by responsible operators). Is there a cement mix which will

hold

up during assembly and over life? Adding more weight would require a bigger

backhoe and stronger safety measures.The total for a 20 X 20 ft building with

wall at back, garage door openings at front could be as little as 120 cu ft.,

per inch of thickness.

Domes next....

Next above is my effort with new software

tools to explore curved geometry. More

can be seen, click here.

In this purely hypothetical CAD model

each arch has most surfaces at 1" thick with a gusset extending along the

whole curved portion of arch, (itself 1" thick). All large surfaces have

a slight ribbing to add strength at joining edges. The main span is 20 ft.

Total

wall/roof volume of each is about 9 cu ft., so wt is about 1170 lbs. If the

straight wall sections are separated and poured flat on the ground, and also

if the curved parts are poured on a sand pile/ mold... and all these are poured

in one or two sessions, then ready mix might be used. Sand casting methods

from

ancient tech apply. A backhoe could be used to lift all pieces into place,

(if safely managed by responsible operators). Is there a cement mix which will

hold

up during assembly and over life? Adding more weight would require a bigger

backhoe and stronger safety measures.The total for a 20 X 20 ft building with

wall at back, garage door openings at front could be as little as 120 cu ft.,

per inch of thickness.

Domes next....

Above is a basket weave , great circle,

lamella cage, mostly in yellow. The green members show the relationship between

the 2 angles used for weaving together the reinforcement members. The scale

becomes important in visualization when doors and windows are cut out of a

CAD model.

Above is a basket weave , great circle,

lamella cage, mostly in yellow. The green members show the relationship between

the 2 angles used for weaving together the reinforcement members. The scale

becomes important in visualization when doors and windows are cut out of a

CAD model.

MXSteve's New Flying Concrete Website

More sites--

For a pretty good ferrocement information site with pictures and links, click here.

A mason friend of mine who lives on a State highway, realized that cement sculpture

was a hot business and quickly developed his own style differing from my sand

molding. He casts oversized rough shapes and then carves the pre-hardened cement.

(Click here to visit his site).

Also I notice through the internet that variations of cement sculpture are catching

on, through out America. I would like to add more www links to this page if

you wish to share your sculptural work methods.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

index.html

2009

2009