A finger formed mesh is shown in first photo below. A very strong, stiff and springy wire is used, (It is manufactured for MIG welding). The finger held mesh is used in the ferrocement work presented further down this page.

2007 experiments with minimalist concrete frameworks.

2007 focus on fast-&-easy ringforcement flat work.

2005 experiments with hand made mesh may be seen here. (Click).

Pre 2004 mesh forming methods are linked here.

Second Photo: A kerf- knotched stick holds wire "rings" which were pre-cut from spool. The kerf notches were cut with a circular saw, (carpenter's framing blade). The wires would spring apart if not held this well.

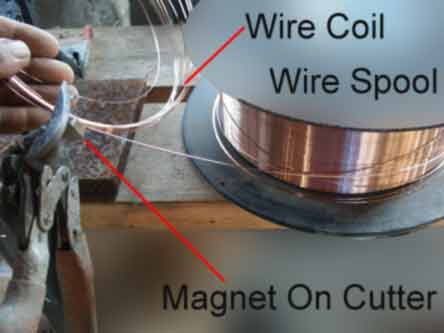

Next photo below shows a wire cutting station to make coils of wire, 8 turns (or loops) each.

Next is the building under construction. A plastic material covers the work area. Following this picture are more pictures taken inside the plastic cover.

Below: A cemenrt coat is "rubbed on" with heal of hand, to eliminate voids. (Right hand holds camera).

Below: A ridge of compacted cement has been made ready first. Then flat coils of wire were placed, with more cement to secure.

After the above step, a hinging mold was clamped in place. The mold has been thinly coated with cement in the "hinged down" possition, (seen below).

Finally below, all the rings are in place ready for final coat. As each set of rings is placed, a small amount of cement is placed to hold them while more rings are added. Also double sized rings are seen. The larger rings are easier to bend around the mold curvature.

Click here to see more ideas about producing wire mesh.

While the welding wire as a primary reinforcement has excellent characteristics for ferrocement, simple methods of using it remain illusive. Agricultural wire is much easier to use but as a thicker gauge is less ideal than thin gauge welding wire. More effort will be made to show examples, here is a small example for the mean time. Here is another example of simple ringforcement using heavier wire.

My friend Steve Korner invited me to try ring reinforcing a lightweight concrete roof in Mexico. A cheap steel wire is widely available there and it was easy to use it. Sizable wire coils easily slid out into a flat spiral. Wish they would sell more low cost, uncoated steel wire in Maine. Mexicans really appreciate the importance of marketing low cost wire, where advanced markets loose sight of the most generic materials.

The broader and bolder hypothesis is that for equal chemistries and weights of steel, finer rings will out perform traditionally-thicker geometries of reinforcement under the same physical tests. Think of it: Nature doesn't use long reinforcement bars, but instead, molecular chains. This ring theory is somewhat modeled on molecular chains, but with cement as a compressive binder. Coincidentally, I've noticed on NOVA/ http://www.pbs.org/wgbh/nova/elegant/program.html --That String Theory has also taken up a form of rings to depict it's theory. What is next?

Wire ring theory also addresses stronger cement mixes, stronger wire and strong monofilament plastics, (like PVA). I would be glad to help prepare samples to test ring reinforcement in competition with other configurations of reinforcement. Until such a lab test opportunity is made available, we are stuck with simpler testing. Steve has come up with his "meteor" test and I hope we can some day compare ring reinforced and other reinforcement configurations. We ran out of time. If inspiration from website responses persist, I might myself try to duplicate his meteor test. I generally prefer testing which employs accurate strain guages which can be simply set up to compair failure levels of competing panels.

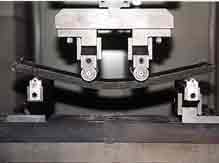

Picture above shows lab testing of a thin cement based panel. I would love to submit ring reinforced panels to test in this way. Anyone?

Little is known about actual test comparisons between traditional reinforcement, flat spiral loops and individual "O" rings. Rings appear to have interesting test possibilities. As a low budget single handed developer, I have very little opportunity to test the many ideas presented in these www pages. The testing cannot keep up with my prototyping nor my conceptual exploration.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson