Here are some integrated green house features, which are intended to economize and to optimize. Smaller greenhouse modeling, primarily for cooler regions, is the focus of this page. Write for other, larger models of eyelid greenhouses.

![]()

This page is geared for adjustable cost of construction, low maintenance and richer-features, for a fixed budget. Groups of small greenhouses can be arranged for preferred solar exposure with contiguous, annualized heat storage. (Slow progress of my eyelid greenhouse prototyping is here.)

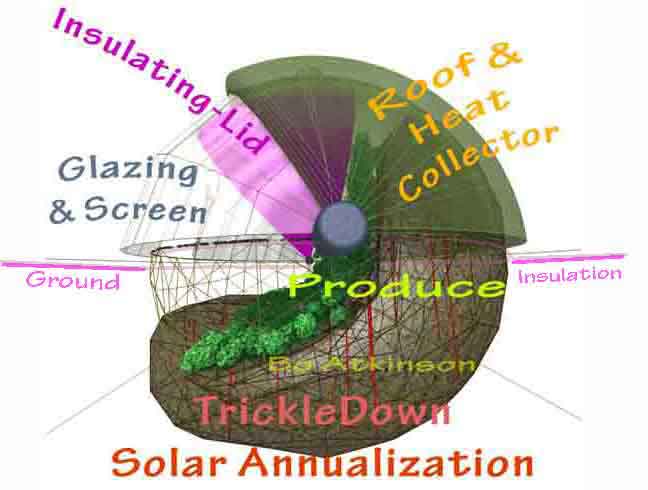

I managed to handle only the challenging ground work in 2009. HVAC is powered by a garden hose? What? Since my own eyelid site is so very wet, i will add my trickle down solar for annualizing heat storage. Solar heat will be simply tricked into the greenhouse soil. While themostatic vlaves will open trickle valve and close it when sunshine decreases. Art work below suggest use of a solar-chimney. The heat of the sun can indeed power a chimney which consequently heats subsoil through convection of summer air.

Too complex? June 2010 ultra simple, stripped down eyelid greenhouse. Click here -- Here is another, much simpler version, compared with the one above, on this page. My simpler version is primarily intended to accelerate bean germination in the ground, at colder latitudes, then open up fully for the warm part of the summer. Visit here later! My page on a low cost "roll-top" and other lowest labor investment 'greenhouses', (especially for extended season and rain-soaked summers). Click away, get ahead of the curb! life can prove joyous for cold-climate garden lovers!

An "Eyelid Greenhouse" is proposed, especially inspired as a competitive structure for produce production. Temperate climates can benefit in one way or another, with duly, customized modifications. Large populations in cool climates could benefit from locally grown produce. The diagram below suggests an unusual, trickle down method for heat storage annualization -- It suggests integrated-harmonization with local ground water, (which should not be agriculturally polluted). Another system approach, using a solar chimney could alternatively draw hot greenhouse air underground through larger tubing (for annualized storage without trickled down water). Far more elaborate systems could employ heat pumps. My experience has been with very small budgets, which tended to inspire the trickle down harmonization concept, for the cool, temperate climate, of water rich Maine. The water controls generally seemed more advantageous, than use of solar-chimney or electric fan controls--Pumping water seems ultimately more efficient than blowing air though both approaches have reasonably priced possibilities.

Cold winters typically require heating a greenhouse with purchased fuels. Greener options take advantage of diverse solar systems. The Eyelid Greenhouse, would store annualized summer heat, beneath the ground surface. Slow conduction of heat would stabilize comfortable levels beyond the foundation, in surrounding, insulated ground. Water can be conserved with customized controls. The process of collecting the heat may also provide some measure of cooling during summer. The proposed growing bed is a tilted-concave, growing-bed. It is reasoned that better sun exposure will result with the shaped mound. Cold climates will receive more winter sun while hot climates could receive more shading options and naturalized-ventilation. The mound also provides an enlarged thermal-storage surface and somewhat stratified heat zones for diverse plant species. An optional, "trickle down" watering scheme can both irrigate and also efficiently annualize comfortable temperature ranges.

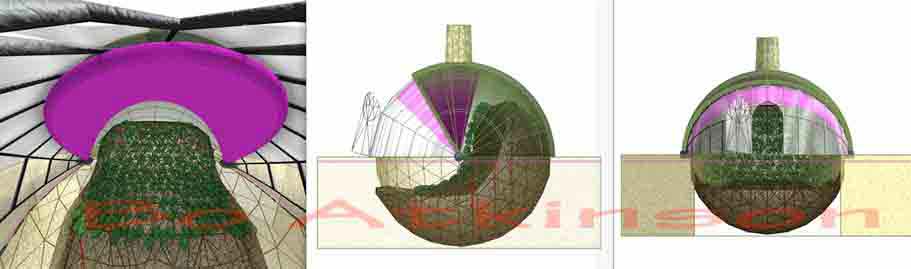

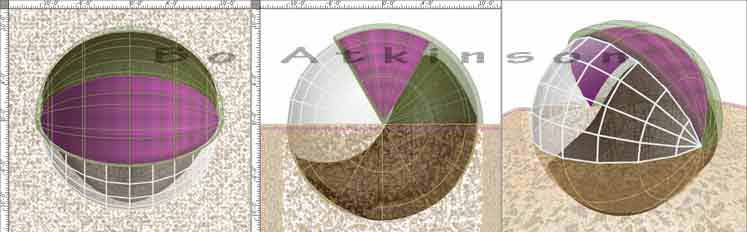

Picture schematically shows glazing shut. (The top view is on left, the side view in the middle and perspective view on right). It is hinged to open upwards and rest beneath the opaque, well-insulated part of the dome. The glazing would remain shut in winter. The ground around the dome would also be continuously insulated, taking advantage of Passive Annualized Heat Storage.

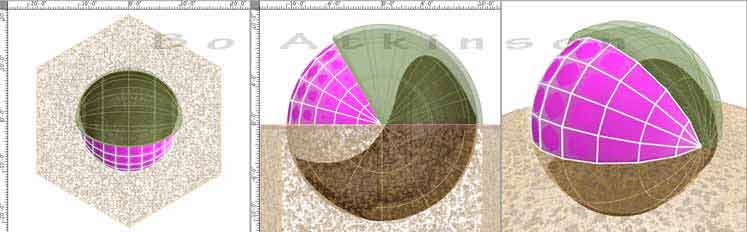

Picture shows the interior-insulating-shutter (purple) in the hinged down position. Considerable insulation is thus provided for cold nights and heat conservation generally. Super insulation is thus available at night (providing frameworks fit very tightly). The opaque (greenish) section of dome is both well insulated and should also function as a solar collector. Solar heated water has been suggested above, but heated air also can contribute to a "solar chimney" effect, for important ventilation (and possibly also for "earth tube" heat storage).

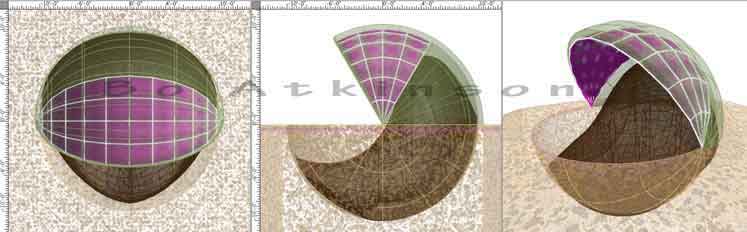

Picture shows the glazing hinged upwards. This enables variable degrees of ventilation, when desired, in the summer. Also, access for maintenance, even for machines, is conceivable. Summer crops are generally provided some noontime shade. Not shown is an optional "bug screen" eyelid. I have detailed other "free-HVAC" greenhouse concepts on this, separate page. Nominal solar chimney and access door are shown next.

Lowest possible operating and building costs might be achieved with many features described below. Recycled styrofoam or selective biomass refuse could generally cover the sub soil, for insulation. A layer of top soil can cap the insulation. The most productive cover would be solar collectors. .Additional solar collection could also be integrated into the surrounding plot of land. This could considerably increase annualized heat harvest. A ferocement-collector-cap would economically provide durability and effective heat collection. That appeals most to me. However, in case other alternative-regional materials, particular scrap or surplus materials, were an objective, i would be glad to help consider alternative design approaches. The prospect of building a group of units can split development cost (jigs, tools, logistics,etc.)

Multiple units could be arrayed together on a hexagonal or a square grid. Sunlight exposure should be studied for optimal proximity, general access and space savings. When arrayed together, savings of perimeter insulation can reduce overall project costs, for cold climates. Hot-dry climates might explore some reversed operation models with earth tubes. The grid array might in fact enhance seasonal stabilization. My favorite design software, formZ offers "animated solar performance analysis" for architects, (to demonstrate sun exposure, for given climates). Such study would take careful familiarization.

Grouping eyelids can reduce perimeter insulation costs and actually improve cost-free HCAV performance. Combine any number as close together as your sun angles permit. The question: how much space is most economical in the long run, for a given need?

Winter equinox, solar exposure is verifiable for given locations, through modeling software.

To further compete with traditionally mass produced greenhouses, additional approaches are noted as follows. (The author has long experience with re-use of discarded materials). The dome shape is not always more difficult to build, (as compared with other greenhouse shapes). I have devoted much of my long life effort to studying comparative translucent building methods, (as in green houses). I have closely studied the process of building with varied materials. This has taught me many cost saving approaches. Glazing frameworks can be built fairly lightweight. Rebar" -steel reinforcing rods are normally used in concrete. The widespread, universal marketing of these rods tends to make their price competitive, in terms of strength and frugality. Instead of welding these rods together (which would require a more complex, tensioned, clamping system for 3d bent surfaces), a simpler binding of junctions with wire is suggested. Additionally, cheap plastic tubing could coat the rods to soften the barbs and provide soft medium for screws,( in some particular applications). Yet smooth steel rods might be found, (though price per weight is typically higher than rebar). Alternatively, greater framework rigidity may be achieved with EMT, light galvanized, electrical conduit tubing. A small MIG welder can weld these, though welding galvanized metal requires extra-safe ventilation. Auto exhaust pipe is also lightweight and generally not galvanized, which could simplify welding safety. Light weight, thin walled, steel tubing is effectively produced, though thin metal is more rust prone. (where a galvanizing process is not available after welding). More elaborate flattened-end bolting can avoid welding. The insulating eye-lid framework might be reinforced with flat bar stock. Wood has not been a problem in my large greenhouse with decades of use, but high grade wood could prove expensive. Each project deserves considerable analysis before localized building materials and methods are chosen.

The least costly greenhouse plastics are available in flexible, single layer, sheet form. The above design can easily be fitted with sheet plastic. I have generally "rolled" together and stapled the resulting, large, loose wrinkles with ordinary paper staples. Actually no cutting of plastic is needed in this approach. The staples may generally last the life-span of a greenhouse-plastic-sheet, which may be a few years, depending on given qualities and exposures. Stainless staples can be found, but are expensive (and rusting staples have been of little concern or ill effect). If the glazing is not needed during summer, it is conveniently hinged and thereby tucked-under the hard roof. This also preserves the plastic, lengthening it's life considerably. It can be hinged back down quickly anytime. If, by chance, seed need be saved and pollination controlled, a fine screen may additionally be fashioned to control pollinating insects, or possibly pests of all kinds. A similar, additional, eyelid-framework can similarly hinge from beneath the insulating-eyelid. (There are some very helpful insects called "beneficials", which must be screened in to prevent escape). A screen-framework "eye-lid" would simply nest underneath the insulating eyelid shutter.

Another important issue is the solar-absorption performance of a structure, (besides the features described above). Large flat, planar surfaces of traditional greenhouse designs, present a more-reflective surface, when the sun angle varies from generally perpendicular exposure. That means that, during mornings and afternoons, less light and heat can be absorbed in traditionally long, rectangular, greenhouse designs. By comparison, domes offer more absorptive sun angles, all day long. In fact teepees and cylindrical shapes somewhat enjoy this same advantage, to some extent. (This general geometric principle is currently benefiting some solar products, even some solar-electric products).

The Heliocaminus design of ancient Rome, pre-dates and encourages many features the above design concepts. I grew up as an American child near ruins like this, (near Rome). It was a pleasant surprise to learn of yet, one more Roman technology, dear to me in several ways. (I missed learning the technical details of this Heliocaminus until 2008 ;)

The author of this page is just one innovator among others. Each innovator may focus on specifically preferred aspects. My interest is very broad. I offer customized computerized modeling which may assist people who wish to communicate these cost saving concepts to their engineers or builders. I also offer customized assistance from earth work to concrete work (and plastic glazing work). Hire me to contract on customized jobs, large or small. Below are other related web pages which i wrote in years past to promote the general "free HVAC" idea.

My blurred images provide faster access for dial up and mobile viewers in addition to saving on my www costs. High resolution images and customized models are available from author. boa1@pivot.net

I offer many diverse structural concepts here.

Bo Atkinson, a fifth generation Atkinson in The USA, still building with earth and stone.

Note: These pages are placed in the public domain and are furnished "as is". The author assumes no responsibility for the use or misuse of the concepts in this series. All authorities should be satisfied first, as might be required, by relevant laws, before any building proceeds.

More on annualized solar-

Searching Synergy .... .... Free Exchange of Ideas

.... Free Exchange of Ideas

Email comments welcome ~~~~~~~ boa1@pivot.net

Tel : 207 342 5796 . . . (Maine)