Many kinds of houses could possibly be retrofitted for free operating costs of HVAC. (HVAC: Heating, Ventilation & Air Conditioning). The focus of this page is on insulating a building along with some surrounding land. Following are some theoretical examples among other research efforts. The first example utilizes a trench which may not be useful for arid regions. A diagrammatic house, with a small square lot is pictured on a plot of land. The features are simplified in order to present the main elements and strategy for cost saving budgets. This is a conceptual model encouraged by excellent results achieved by legacy- earthshelters.com, government funded research.

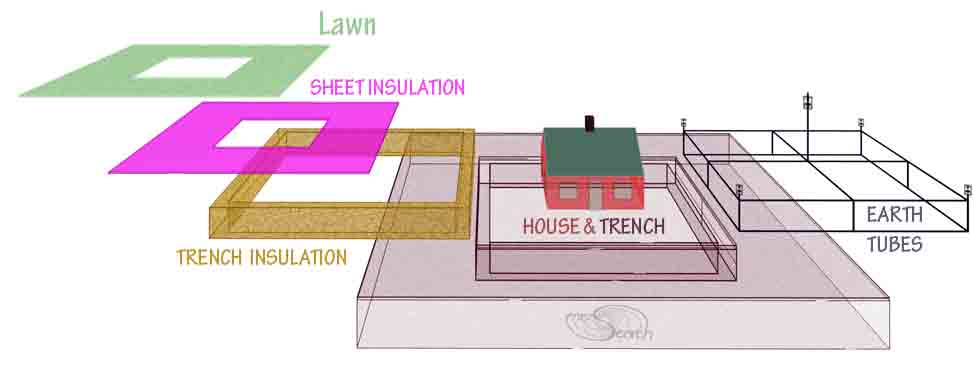

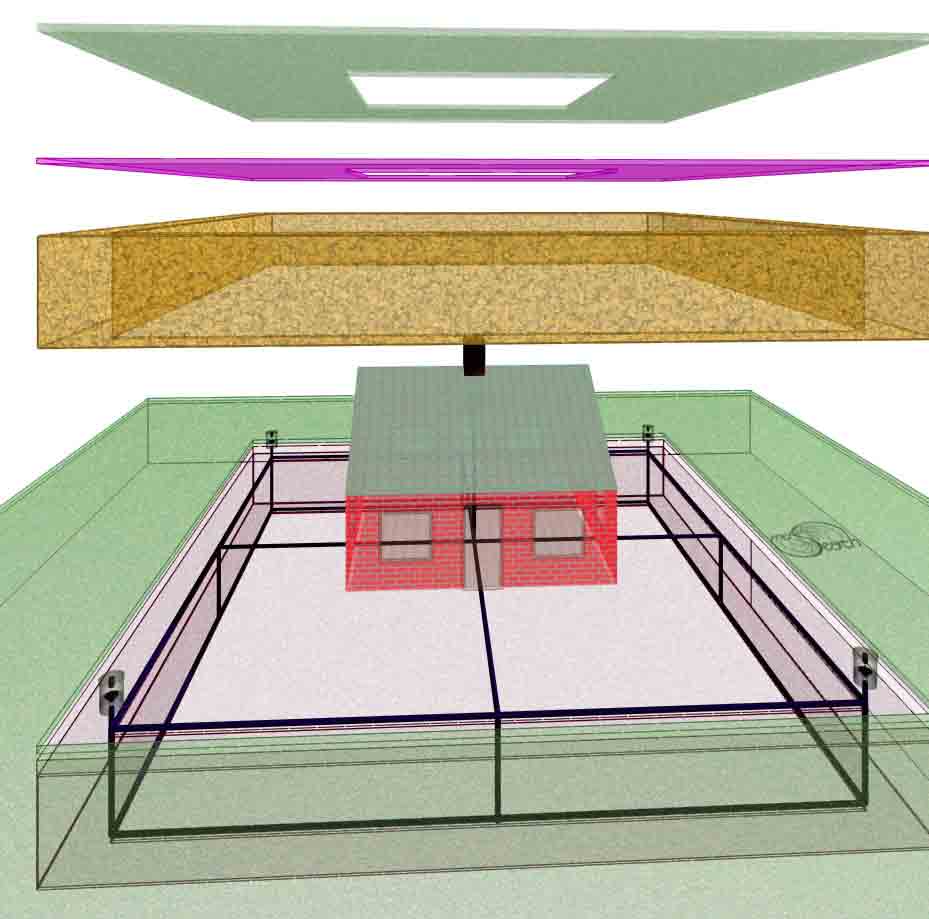

The next picture below dissects the main features to be installed. To the left are "pulled away" the lawn, the sheet insulation and the trench insulation. Use of a trench is favorable in cases of space limitations and/or for diverting potential ground water. If water should be expected or encountered. Trench insulation could theoretically be any suitable, low cost insulation material such as recyclables, or locally harvested product. Bulk insulation materials could also be local byproducts or surplus to reduce costs. Commercially branded sheet insulation may in some other cases be preferred for pure conventionality. Yet optional bulk insulation could potentially result in huge cost savings. Most bulk insulation requires larger volumes of space or else the requirement to move soil. New construction can sometimes absorb all costs of this type of earth moving. On the right of the house pictured below, is an assembly of earth tubes which have been drawn outside of the trench for clarity.

Bulk insulation dumped into the trench and covered might even consist of organic waste products such as saw mill or selective-agricultural wastes and preserved in the trench. Without critical supply of oxygen, moisture and nitrogenous components, organic fill material highly resists decomposition. There are some suitably dry sites, but thorough investigation of site potentials is needed first. Wet soils would need stronger provisions made first. However the bottom earth tubes should adequately drain moderate amounts of ground water. Outer trench wall must be very well sealed in a manner to ward off rodents and prevent accidental breaching. Once the system is stabilized, the "warmth" can adequately "repel" underground moisture. (The active principle of long term, gradual condensation is suggested here which tends to force water to cooler surrounding soils.)

The earth tubes (in black) as configured in image above, can provide heat distribution by convection of air. The air flow is controlled according to the season and without consumption of fuel or other commercial energy. Vents could be attached to the earth tubes, to open and close by use of thermally activated pistons. Thermal vent openers have been developed for greenhouses, which generally activate at "comfortable temperatures" (i.e. near to 70º F). Herein lies the cost savings of HVAC without monthly bills and without need for endless wars wagged to enrich insatiable life styles. Air movement can be energized either by natural solar-chimney draft or by solar fans or both. Site evaluation is important to adapt the best plan for the given locality, owner preferences and applicable, local building codes. There are certainly other earth tube system plans, which do vary from this schematic. This particular system is more suited to address ground water in wet soils. Yet it needs some trial efforts before claims are made.

.

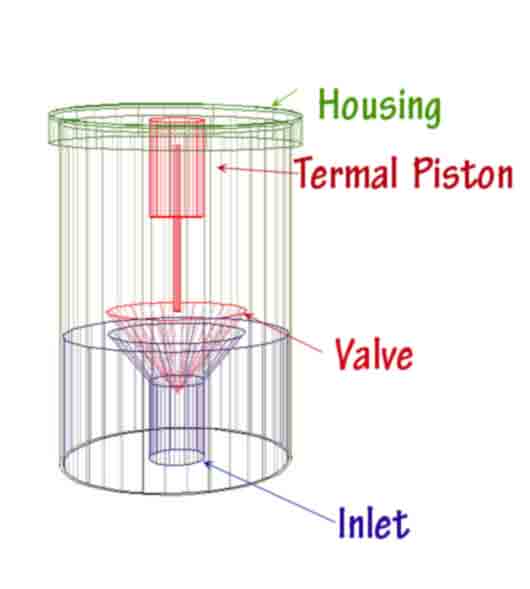

Another variation would be forcing hotter solar heat downwards, near to the house center. The small illustration above implies that a warmer mass would result, well below the ground surface and become moderated by the time it reaches the floor surface and the living space. It could possibly be powered by a solar chimney of sufficient size, though basic verification is prudent to try first. Next a general style of thermal valve is suggested for automatically controlling out door vents. Additionally, a solar chimney would also need heat powered controls. (Search: "vent opener"to see a variety of products. These avoid the more expensive electronic controls.)

Thermal valves could theoretically be adapted but need more study first. A thermal piston valve assembly is visualized above. In this theoretical design, a (reverse acting) piston setup which lifts the valve open when the temperature reaches a comfortably warm range is visualized. A conic shape is predicted to increase opening size sooner than other (naturally activated) configurations. A thickly insulated inlet area is needed to "seal" the thermal comfort zone (in the earth). In some regions, the thermal valve may be omitted to save on costs. Early system trials should include careful monitoring to verify system preferences or adjustments. Extreme climates within the viable temperate range may have to be manually overridden to seal these vents and stop air flow when the ground storage temperatures exceed desirable ranges. At this writing, such valves have not been noted in other research for the same purpose. Further research calls out to brave individuals, because prominent authorities have ignored energy saving strategies. Older architectural systems like adobe have been under rated instead of upgraded with house-lot insulation.

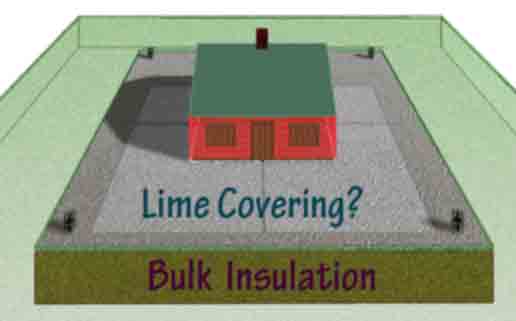

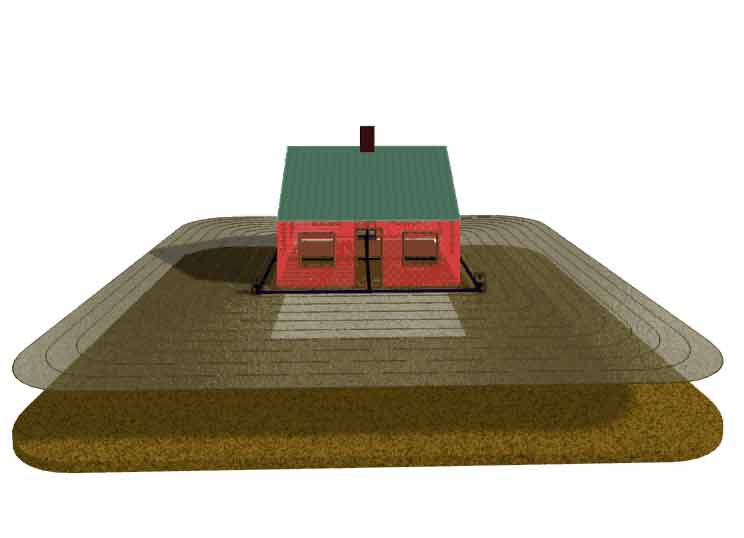

The picture above suggests the possibility of lime as a ground surface sealer (under lying the landscaping or lawn). An appropriately compacted pitch drains the surface, lime or clay mixes might provide adequate sealing. Lime "plaster" has been observed to somewhat "self heal cracks". Another alternative material might feature discarded sheet rock material (which is largely gypsum. Still another possibility is waste paper, where aridity may allow it. (Plastic sheet is susceptible to undetected puncture. Also, spreading fine materials is much easier in case of rough and rocky soils, assuming cost saving sources). Many aspects should be reviewed and the best options developed further. The image below presents an installation without surrounding trench, for an arid-temperate region. A thick layer of bulk insulating material could be used instead of commercially sold sheet insulation. The surface and edges would need a strategy to prevent rodent or accidental breaching.

(old link removed from www). I contacted a local university recycling effort. There is hope society will solve some waste problems through material-reuse marketing. Cement manufacturer byproducts can include huge piles of limey fly-ash which is under utilized (or wasted). Here is an entrepreneurial opportunity for able business people to attempt buying and utilizing a troublesome limey waste. Use it productively and safely. My local cement producer forbade small scale research. Yet a person or company of means might be treated much better. (I operate on a very small cash flow).

Annualized- Log Cabin Style? I've always appreciated, that, much of northern humanity used log home construction (throughout history). At least one friend agrees with me that super savings could be had with "sweat equity". The woods of Maine, for example, will greatly benefit by thinning out saplings (and letting better trees have more light with more air circulation, "silva culture"). For the most part this kind of thinning collects biomass of little value and generally would cost too much to gather and grind up into mulch or chips. I refer specifically to wood which is generally diseased and too flimsy to use as fire wood. Also fire wood production usually wastes the tree tops which also fall into this category. such material is often too disbursed for profitable wood-chip harvesting, in the case where clear cutting is not wanted. Why not use chain saws to simply cut such brush piles into short pieces, say under 3 ft or one meter long? I normally mulch this way, quickly and easily (instead of using expensive motorized chippers). Now, my "further-more" thought is: Why not use a landscaping tractor to spread this material over the ground to be insulated. A crawler-tread tractor could trample this brush-like-mulch material into a large insulation-worthy layer. With finer material added on top, it could finally be capped with earth. Rot would be negligible for decades and not diminish insulation value. perhaps after centuries, rot would finally turn into humus, which is an excellent soils remediation feature. Carbon sequestration would be considerable and favorable, as compared with other insulating methods.

My interest is in system modeling, efficient building systems, earth work and re-use of otherwise wasted materials.

\Note: These pages are placed in the public domain and are furnished "as is". The author assumes no responsibility for the use or misuse of the concepts in this series. All pertaining laws of life should be satisfied, in building or testing my concepts or descriptions, as are posted on my linked pages.