Translucent Roofing Replacement

This page will demonstrate how a dome was sheathed with poly carbonate structured plastic sheet (GE Lexan Brand). The (partial) dome is 42 ft in diameter at base, with a 14 ft diameter deck on top. The original dome sheathing was fiberglass. The additional layered installation was applied nearly fifteen years after the first layer, (as described on this page). Lexan literature claimed clarity for 10 years, but i noticed yellowing to begin much sooner than that. The fatigue of this plastic deserves more notice, due to it's characteristic expansion and contraction from day to night. After about 10 years, cracks became noticeable, which is far more serious than yellowing. Worse yet, there are no coatings which match the daily shrinkage and expansion. Failure is guaranteed. Plastic is simply too short lived for our world and oil companies overly promote inferior product formulations. Durable translucencey in a flexible sheet material has not been available to my knowledge. Perhaps it is because transparency is attempted when durable-translucency alone is more important.Yet my exploration of the building process is not regretted. Roofing and attics are natural solar collectors and live green spaces can provide a great benefit. One day durable translucency in a flexible sheet might be achieved.

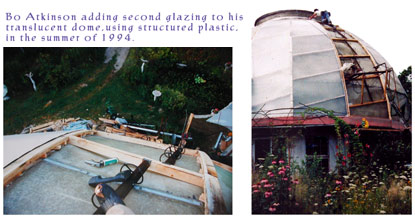

First picture to left is from a high perch looking down at the sheathing process. Second picture above to right is from the garden below looking up at work progress. This poly carbonate re-sheathing was added to the existing fiberglass dome. I originally built the fiberglass dome in 1980, (click here for some details). These new layers were primarily added for insulation value, and to preserve the aging fiberglass.The wide spans have proven durable through one hurricane, (Gloria). While the original fiberglass was placed with horizontal edges, the structured plastic was placed at an angle for two reasons. The rain drainage is hereby better focused away from the arch seams. Sloping purlins naturally measure closer to dome center, respective to main arches, (hence better runoff). Also, should condensate buildup within the structured sheet, it is better encouraged to drain down slope, or so i reasoned. Provision was made to allow all of the structured channels to "breath through small openings-- only at top and bottom of arches. Wood purlins were used to allow easy screwing of sheathing to frame. Triangular bracing to resist swaying of the building was partly achieved through the high tensile strength of the plastic sheets. Further bracing is added through solid wall partitions and floors inside the dome. (Admittedly, though, this poly carbide plastic expands and contracts too much to take full advantage of it's bracing contribution. Thermal stability would be much preferred, but this imperfection is tolerable. The ultimate failure of this plastic is inability to endure UV rays from the sun).

Next above is a sample of structured plastic which has been "kerfed", to allow integral lapping. A table saw was used to rip out some edge ribs from the structured plastic. Lapping relaxes the sheets at the seams so that screws may be torqued firmly to secure plastic and provide tensile integrity with the overall structure. This practice is frowned on by the manufacturers, but the strength property, of plastic is useful. Manufacture's caulking was used (silicone) to dress the seams and fill the hollow washer, (shown in the picture). Stainless screws were used. The hollow, stainless steel "finishing washers" were used along the sloping seams, though larger diameter washers help compensate for the poly-carbide fatigue and aging. Aluminum batons were used along the main arches. (Click here to read about another issue: How this baton arrangement can reduce atmospheric charge which becomes lightning... Tesla's lightning protector!)

Next above is a picture of staging at the juncture between this dome and a concave, sloping roof section. Note use of simple scaffolding. The length of time used to re-sheath each section of the dome averaged: perhaps 16 to 20 hours, (single handed). (This work included removing and recycling of the main aluminum batons of the main arches and the scaffolding). These alloyed aluminum batons consisted of (approximately) 1/16" X 3.5 " X 48" aluminum, which were scraped and scoured clean. Norton's permanent foam tape was applied beneath both edges followed with new caulking for a compression seal and foam filled screw holes. (Pictures temporarily lost in stacks of slides and negatives, from the pre digital imaging days). After seasons of winter ice and summer heat, this sheathing system holds up well, except of course that poly carbonate plastic turns hazy and weakens due to sun exposure. The near transparency of brand new poly carbide seems to me of little value. Instead, formulating plastic to withstand the UV rays from the sun should be the main selling point. Due to the high humidity of the greenhouse, some insignificant condensation does form in cold weather.

See the solar attic greenhouse inside of this translucent dome.

Bo's latest and best construction related links are to be found here.

This dome made it to the cover of Home Power magazine , Issue #39 Aug/Sept 1993

Left: Ferrocement kitchen sink and counter built in 1978.