Living in a green roof garden, in cold climates, is possible, as seen in first photos. Many layers of plastic serve in an "envelope insulation system" which uses green house (or conservatory) spaces as a "partial thermal insulator". Second photo: inside a solar attic rose garden. An Italian saying suggests: "forgive the thorns for the beauty of the rose". The challenge of living inside a greenhouse is climate control. Either some tolerance to tasteful imperfection is required or else climate control expenses are imposed. We chose economical tolerance and happily managed this at low cost, (continuously for decades).

Above:1995 Photos A second glazing or covering was added directly over the first fibre glass glazing, (which was installed in 1980). I would offer more pictures here except that media-styling is not my point, rather i am promoting the exploration of harmonious life styles. In this regard we had to build with a very small budget and for the most part single handed). This dome is located in a temperate climate with frozen winters, in Maine USA. My wife, who tends her floral greenhouse spaces, accepted mostly live soil conditioning, which introduces a complex 'wild' ecosystem. This requires continued work for the occupant and tender, but this kind of work is useful as an alternative, practical exercise. As visionaries, we evolved and interacted with IPM (Integrated Pest Management). We have explored living closely with live ecosystems. Most of the work involves watering, tending to ventilation hatches, careful clean up of plant-invader debris and fostering of beneficials.

Transpiration by plants and evaporation generally improve indoor humidity. Un-automated, colder climate dwellings can tend to dry the interior atmosphere. We rarely got high humidity weather patterns, between the 1970s and the 2000s. I've not observed house mold issues or problems as might be asked. (This was a humidity level which was humanly comfortable and clearly contrasts with unconformable humidity). We never got around to mechanized HVAC, with automatic controls-- These are actually expensive systems and energy demanding, compared to our low budget, passive approach. The current HVAC market is fixated in heavily mechanized, non biological means of comfort control.

Frankly, i suspect that humidity "grounds out" or reduces electrical charges indoors and in so doing suppresses mild EMR pollution, (EMR means Electromagnetic Radiation). As i love Nikola Tesla's legacy, EMR pollution worries me less. I expect that intense radiation from cell phones and excessive wireless gadgetry can stress life needlessly. Mild EMR is unavoidable and i believe moderate humidity solves some associated radiation issues, through electrical dissipation in the humid air. Except where a person suffers from severe sensitivities and vulnerabilities. (We do not suffer such things).

Moreover, a good level of humidity tends to weigh down dust particles, so that we need not breath them in. Broom sweeping becomes far less dusty. Compared with little ionizer devices which i tested. Live plants or even drying green firewood indoors, has maintained wanted humidity levels and ultimately costs less. I noticed that the ionizers tended to wear out the electrodes too soon and such maintenance is less fun than plant maintenance.

The attic greenhouse works like a huge solar chimney when the vent is open. We partitioned the dome interior and zoned the climate levels. The attic climate swings widely between sun up and down. The attic never freezes nor fries the roses within it. Plant pests are always a great concern from insects to mildew as we have explored what is possible without use of commercial pesticides or toxic chemicals. I have observed commercial green house operators with health consequences due to agro- chemical treatments. My wife has tried a number of organic remedies,(bio degradable and generally non-toxic). This includes numerous strategies of pest management, especially organisms called beneficials. I will try to briefly describe several as follows.

We have wondered if purchased lizards survive well. Every once in a while one was seen, catching a fly or just quietly sunning itself, or lapping water from a leaf. We hope the lizards find other beneficials too slow moving to interest them (as lizards hunt acrobatically with speed but never attack or bite humans). I could try to photograph each beneficial but my camera is poor for close up pictures. Besides the internet has great photos and links already. We love lace wings but rarely see any, while many have been purchased and released inside. (We can only hope they are not lost to the lizards?). Crypts are often visible in the larval stage. Lady bugs come with the wind and are welcomed. It was a pleasant surprise to learn that lightning bugs are beneficials, though the very few we captured have not been noticed much indoors, as yet. North Eastern USA has abundant fireflies, spread the word, they are beneficials!

Also an apparently good control for mildew is simple pressurized water spray followed by floor sweeping up. We get very little ventilation during winter due to conserving heat. Electric fans can use a lot of expensive AC power. Solar fans may one day make sense but the capacity needed is expensive. Another hope in my heart is use of ultra violet light treatment or perhaps ionized air or both. I bought a small unit but it was hard to tell if it accomplishes much. A big unit or selective frequency spectrums might do more, but it is hard to manage purchases like that. (Due to lack of benign research budgets, on a planet devoted so much to perpetual wars for profits). Sadly, the ultra violet sun rays (UV) are filtered out by the dome shelter and the UV also wears out almost any material over time. With patience, society may yet find better building materials to let just enough UV in, as does the atmosphere. Developing a green thumb attitude really has been essential, but i am impressed at the crop of flowers and figs (an assorted foods). We now patiently are trying avocados and peppers which can't propagate outdoors (here in Maine).

The floors beneath ensconces a smaller orchid greenhouse to the south and other insulated rooms. My wife is primarily interested in flower research. As wedding flowers have proved our best income source, over the years. Better, actually, than was my sculptural concrete contracting work. I never once had a request to build a solar attic garden space-- Heh, heh, what was i thinking? That visionary work sells? Mine hasn't sold, but i find great solace in my visionary lifestyle. I never could afford promotion, outside of my website. Yet i do believe that the ages of strife will self-implode, all in due course. So that the visionary must take satisfaction in that alone.

_

_

Natural lighting through a dozen layers of plastic sensitizes the 2nd floor rooms to daytime living. We have never felt it worthwhile to add insulating curtains, but originally intended more partitioning. The skylight aperture is too large to do this easily or economically. Nor have we chosen to reduce the day light aperture, by adding some opaque insulation. While the insulation value could be far higher with opaque insulation, we accept the loss of perfect climate control. We found ways to moderate natural ventilation with interior partitions and floors. We love the natural daytime lighting. Ultimately i believe that affordable translucent insulation will be marketed.

_ _

_ _

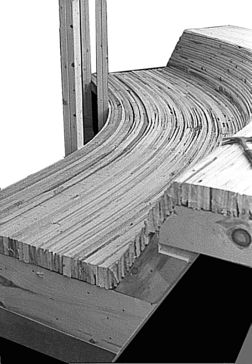

Next photos above: First, a picture of green house bench under construction (in the 1980s). Next a view looking up from ground floor underneath the orchid green house bench. These were coated with waterproofing. However all the floor surfaces were eventually covered with rubber roof sheeting. Rubber roof material has proven far more effective to waterproof entire floors. Thin coating materials from ferrocement to rubberized coatings all developed leaks, eventually.

An old sketch drawn with a by gone software program, illustrates the original design objectives which were experimented with, (click here). Below are snap shots taken while building the dome with laminated arches. Each arch was built in "dog clamps" on the second floor, (see 2nd picture below). Lightweight cedar was used which allowed me to raise each arch while I worked alone, (no help, my wife hates climbing). It took about 7 months in 1980, (to build the translucent dome shell single handed). As can be seen below, this dome intersects an existing old, run down cape house. The dome covered and replaced some of the cape house. The materials costs were paid out of earnings, from year to year. About 2000 sq. ft. of fiberglass sheathing was used in one layer, 40 mils thick. Materials for the 42 ft. dome cost about $3,000 in 1980. Soon after finishing the dome, additional layers of copolymer plastic sheeting were added from inside for insulation. Some 2nd floor areas still intact after 25 years, received 9 layers of co-poly with air spaces between each plastic layer. Interiors are still in various stages of deferred completion. Good thing my wife and i didn't get a mortgage, being without debt leaves time to explore freedom.

. . .

. . .

The original fiberglass sheathing lasted 15 years, even through one hurricane, "Gloria". The first layer did develop insignificant sealant leaks due to the simple linseed oil based sealant used, (@ 30 cents per tube). The fiberglass used was not the premium grade and at some year between, we "painted" it with a special resin, sold by the fiberglass manufacturer. I mounted a regular paint roller on to a 16 ft. pole and laboriously painted most all dome surfaces. Reaching from the ground and from the deck on top. This "cemented" all the loosening fibers where the original resin had worn away.

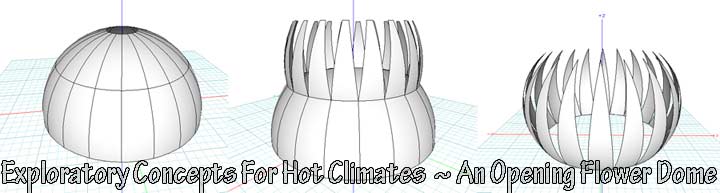

We would have liked to build very large opening sections, to let in full sunlight and more ventilation. Besides an effort to draw out practical implications, there are unrelenting difficulties building tight seals which are durable. This was much too expensive for us to consider further and we were eager to see just what we could accomplish without loans or better resources. (The internet full of information like this was not available until well after year 2000.

Even after several decades, we are quite satisfied with small vent openings on top, which provide considerable ventilation in summer weather, (Maine, USA). In summer, the ferrocement-masonry of the first level, cools down with cool night air and holds coolth in for the summer daytime, (with shut doors and windows on first level). The second and third level greenhouses heat up, but living space is buffered interiorly, with concentric partitions for living spaces. In winter, all is shut tight, which allows enough ventilation, regardless, (due to our small building budget, with many imperfections). Some more evolved concepts of green houses are linked here. Please excuse my very limited writings. I do welcome further discussions through email or skype, etc..

![]()

The first picture, (top of page), shows my innovation of sloping purlins, which increases the runoff "valley" effect between the main arches. (Click here for a page with some details on re- sheathing process). Below is a photo from the fiberglass dome's first winter which shows the level purlins These purlins were very minimally, just enough to hold screws. In addition to them, i mistakenly reasoned that roving would be a good additional measure to add. So while sheathing the fiberglass dome, the rope like roving was first stretched in place, and later coated with resin, which "glued" it to the sheathing. Admittedly, this roving was a wasted effort.

I have been asked: what is the best translucent material. Durable translucency in a flexible sheet material has not been available to my knowledge, at acceptable prices. Perhaps it is because transparency is attempted by the industry, which is more technically difficult to achieve. Transparency adds very little benefit, from my perspective. Insulating-translucency alone is the essential characteristic needed. Insulation is also difficult to obtain, at reasonable cost for building housing. My exploration of this building experience seemed very worthwhile, despite hardships. One day durable translucency in a flexible sheet (to accommodate compound curvature), might be achieved by humanity.

I wanted to promote translucent attics and also translucent shells, for 2 or 3 floors of a home. This might have seemed too boldly experimental for housing markets. I was nevertheless grateful to explore the energizing aspects of this life style while we humans actually do live in failing models of existence. I feel we should be inspired by the necessity to evolve while it is still possible.

The down stairs (vertical, cylindrical wall), is ferrocement, built in 1976. I was very interested in ferrocement at first, but have now begun exploring a new synergy of ferrocement, concrete and old masonry methods. (Curved construction is also key in this study.)

Some old work links are to be found here.

This dome made it to the cover of Home Power magazine , Issue #39 Aug/Sept 1993

"cap-it-all" solar attic with silica gel.

See laminated wooden fixtures to fit curved walls.

Poorman's greenhouses, cold frames and blight research.

Left: Ferrocement kitchen sink and counter built in 1978.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson