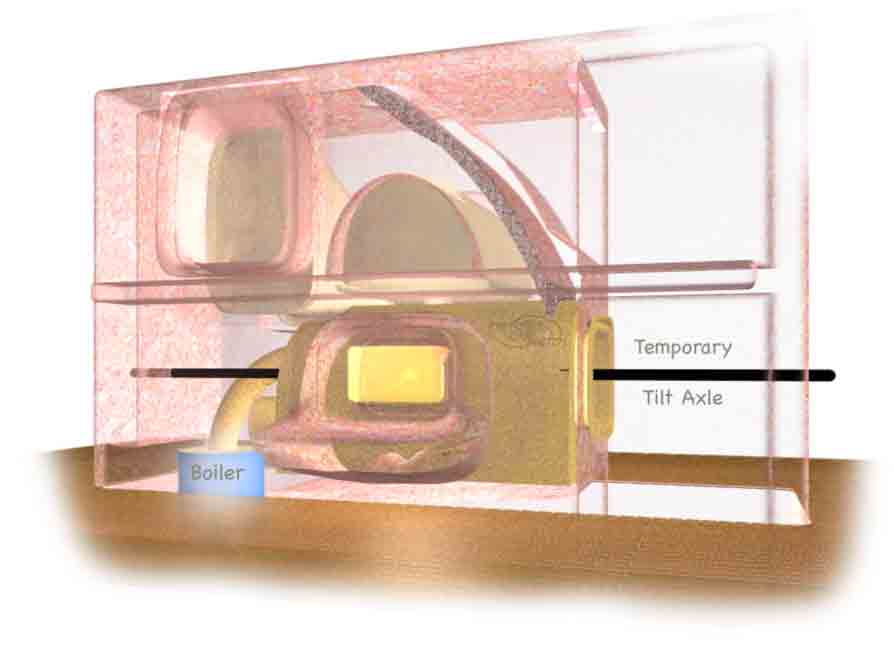

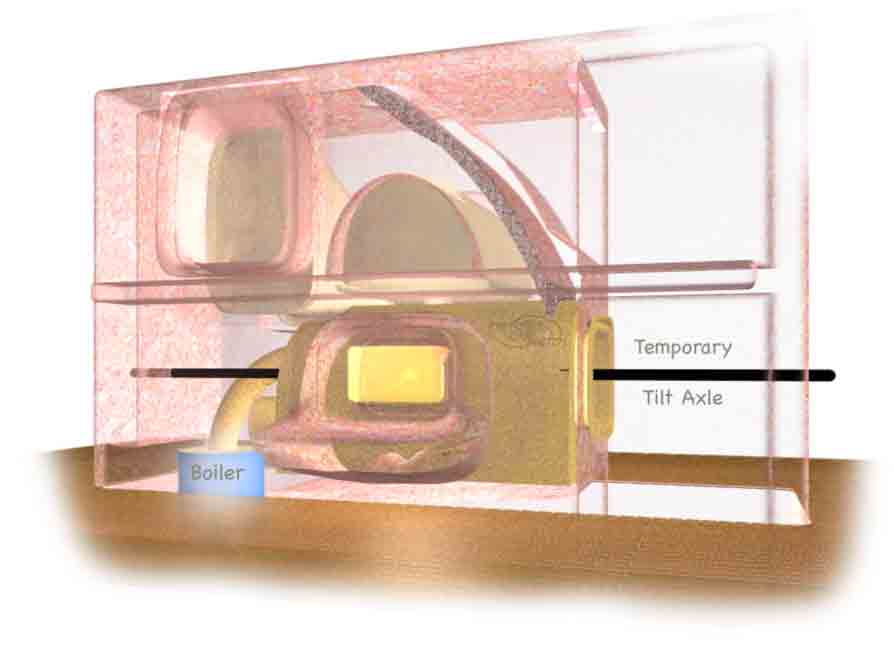

Semi Transparent View

Essentially Monolithic Furnace -- Balanced Tilt Up Proposition

Semi Transparent View

CAD precision fits together all the features and more. Familiar features

for masonry heaters are a fireplace-window, cooking-oven, cooking-range.

Less common

features are wood-driers, warming-cubbies and hot-water. Here is a

model which combines as many features as possible. The critical vapor seal

required for masonry heaters is addressed with as much monolithic pouring

as is possible. Working the primary wall surfaces flat, with the aid of

gravity, will best insure the highest possible quality. Therefore the

challenging technique of tilt up construction is offered.

This model is intended primarily for study and inspiration. The current 3D

Cad model is available. Inquiries of all kinds are welcome. Telephone

number and Email address is provided below,

at page bottom.

An insulated fire box simplifies fire-making chores and efficient burning. A cordwood sized firebox offers advantages and is included in this particular model. Labor can be saved with less splitting and cutting. An un-insulated firebox can loose too much heat through it's walls. It can take a while to heat up. Unburned fuel is wasted and for longer periods it pollutes the exhaust.

Refractory insulation is not cheap but is like investing money in a useful tool. Cordwood is cheaper for equal heating value, compared with pieces of wood cut short. House-customization can greatly ease cordwood handling. For the frugal-minded wood user, long, insulated fireboxes can make use of wasted brush piles. Collecting longer pieces of wasted wood is less troublesome than cutting and handling short pieces. Ordinary cordwood offers sufficient output for co-generation of electricity with a small steam-generator. (Although such a device would have to be custom built as of 2006). Domestic co-generation would provide excellent backup for the all-solar home. (Shorter 3 ft or 1 meter sized wood makes more sense, especially if harvested oneself. However, the American market is locked into 4 ft cordwood "packaging"). With experience, one can learn to burn "green wood" and generally un-ideal firewood. Best of all, such heaters function without need of electric blowers.

Addition of a small heat-storage-hearth around the base would extend

the heat storage capacity. In fact, this system would highly compliment

PAHS-AGS

houses.

Engineering-redundancy is well respected in a world where so much goes

wrong. Comfort and convenience demand comprehensive dual-use design as

backups.

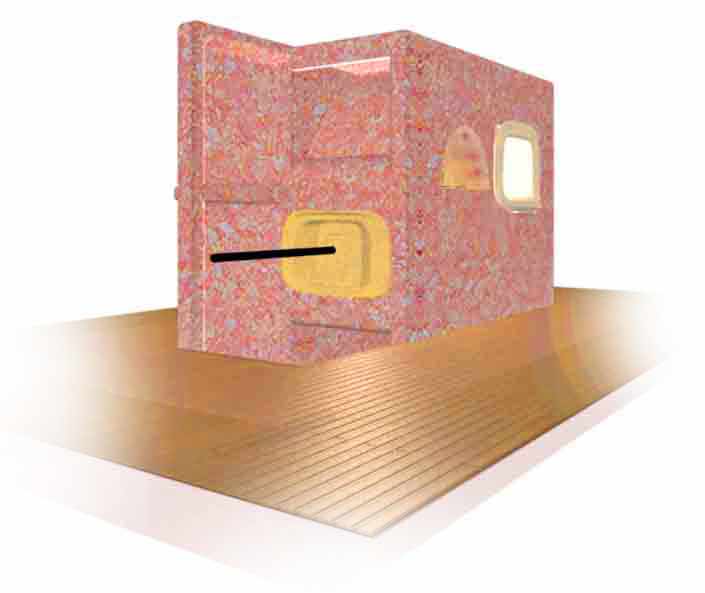

The feature of artistic and balanced tilt up construction allows for the highest concrete standards to be achieved with the least expense. Instead of one cookie-cutter, commercialist approach, a personalized touch is possible with texture, color and further individualization. The refractory components could be factory derived or sand-cast by a competent artisan. Once made these components doubly serve as much of the internal form work.

Pictures above portray texture derived from real leaves. It is a ferrocement fireplace built to accommodate a gas fire and is presented only as a sample of leaf texture. Here is how leaf texture can be incorporated. Leaves would be placed upon the main tilting platform. A colorful cement slurry would be sprayed over them, to form a gel coat. Then would begin a monolithic concrete pour. After the first wall is poured flat and compacted, prefab parts and wall forms would be placed.

The picture above is a lay-out example which could be used to guide placement of components in a wall. Next picture below: Further components are placed on top of pour. Panel sections can be placed along with other components, all of which could be sand cast in advance. (The tilting axle is not pictured, nor is the needed braced stand.) Various flue dampers and other details are needed to keep heat where it is wanted. Concrete cannot receive high heat directly. Heat must be carefully channeled and dispersed before reaching the concrete surfaces. This a safe strategy. Mixes better than ordinary concrete are feasible. However, true refractories require high firing to gain useful strength. According to rule of thumb, Portland based concrete should not be heated much higher than food baking temperatures. Even castable refractories loose strength as temperature rises near to glowing hot and must reach higher fusion temperatures before gaining a ceramic bond.

To complete the concrete sandwich: The opposing wall would be poured on top, (and textured). With skilled people, this could happen fast. Use of ready-mix concrete tends to speed work further. Use of ready-mix truck fitted with a boom could save labor assuming adequate pumping equipment is not available. Otherwise, able laborers could use a portable mixer and still complete the pour in a day. (As drawn, the amount of concrete is around 4 cubic yards or 4 cubic meters. This amount of ready mix can be delivered without surcharge for small loads).) Finally, after sufficient curing, the whole composite sandwich is balance-tilted upright, (pivoted on an axle).

The point is, this might be done efficiently and it can be done with little equipment investment. It could be done in new construction sites or in retrofits. The tilted pour allows the finished surfaces to receive the most careful treatment and the most durable compaction, (in the shortest labor time). This aids both the aesthetics and the ultimate strength. Computer aided layout ushers in new advantages for customizing jobs to better suit clients and architects.

By contrast, purely masonry technique is also possible. However achieving an equal vapor seal is difficult. Providing equal reinforcement is also more difficult with masonry. Coatings in masonry are less stable than are monolithic poured members. An advantage of masonry may be that stress distribution hides failures in the numerous brick seams. Monolithic disadvantage may be that differential stresses could concentrate more noticeable cracks. These issues call for the best workmanship practices and the effort to equalize heating in all parts of the structure.

Vortex Flame Amplifier : Solid Fuel Burner Experimentation

Insulated Firebox Experimentation

Bo's Art Of Burning In Ordinary Stoves (Link to be added)

Note: These pages are placed in the public domain and are furnished "as is". The author assumes no responsibility for the use or misuse of the concepts in this series. All authorities should be satisfied first, as might be required, by relevant laws, before any building proceeds.

Searching Synergy .... .... Free Exchange of Ideas

.... Free Exchange of Ideas

Enersearch was incorporated in 1980 but never materialized financially. A synergy of concepts were developed and are reflected in the pages of this series. The synergy continues as a single handed effort of Bo Atkinson, in Maine, USA.