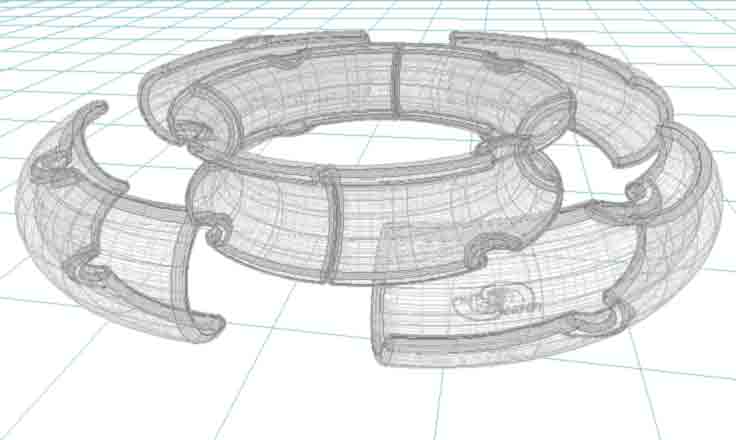

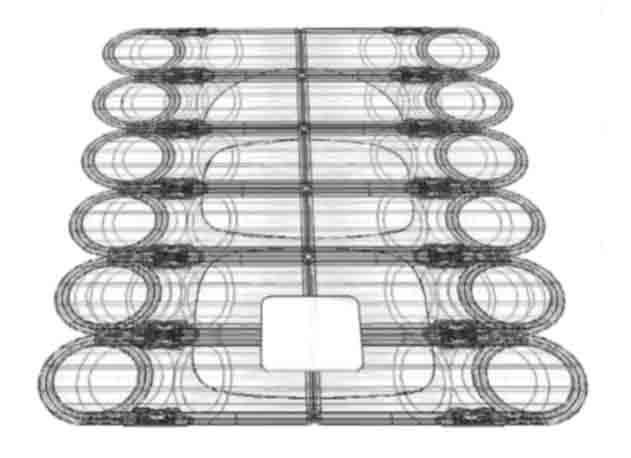

Hollow torus-shaped

flues can stack up to make a counter-flow masonry heater. Theory: Spiral

draft flows are

induced by tangential, intersecting, smaller,

vertical flues.

Hollow torus-shaped

flues can stack up to make a counter-flow masonry heater. Theory: Spiral

draft flows are

induced by tangential, intersecting, smaller,

vertical flues.

Spiral Donut Core

With Ovens, Fireplace, Firebox & More. One of my furnace friends felt i should cite Rudolf Steiner concerning any use of spirals in a furnace. I do actually recall seeing a book which illustrated a continuous spiral path made of tiles or bricks for a flue core, crediting Steiner. The design below is naturally inspired by Eurasian/Scandinavian designs and also Steiner, yet this design adds further, diverse features. In terms of traditional wood stoves-- A book entitled "Helping people in poor countries Develop Fuel-Saving Stoves", produced by Aprovecho (Oregon, USA), has collected many interesting design styles, (of differing traditional stove designs from around the world).  Hollow torus-shaped

flues can stack up to make a counter-flow masonry heater. Theory: Spiral

draft flows are

induced by tangential, intersecting, smaller,

vertical flues.

Hollow torus-shaped

flues can stack up to make a counter-flow masonry heater. Theory: Spiral

draft flows are

induced by tangential, intersecting, smaller,

vertical flues.

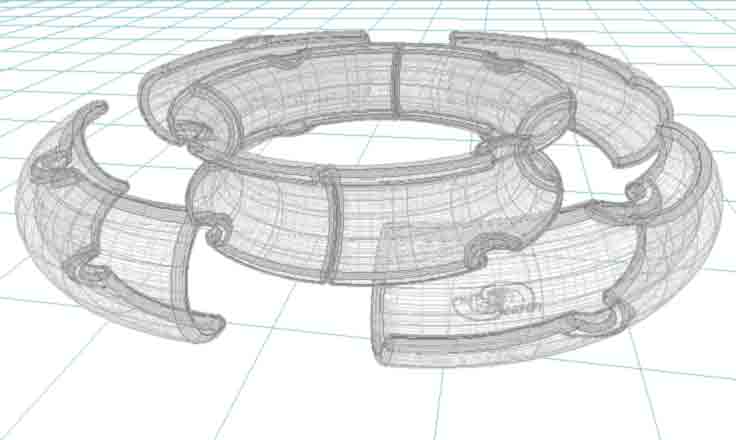

Tangential to the small torus radii, small vertical flues induce circular flow in all tori (donuts). In turn, this circular flow may induce further lateral exhaust movement. This increased circulation enhances heat exchange and distributed heat storage.

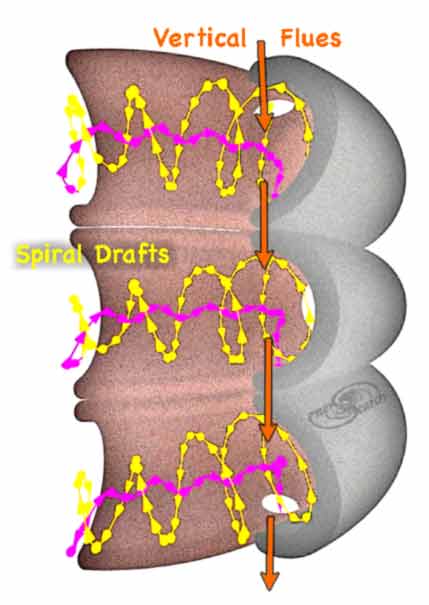

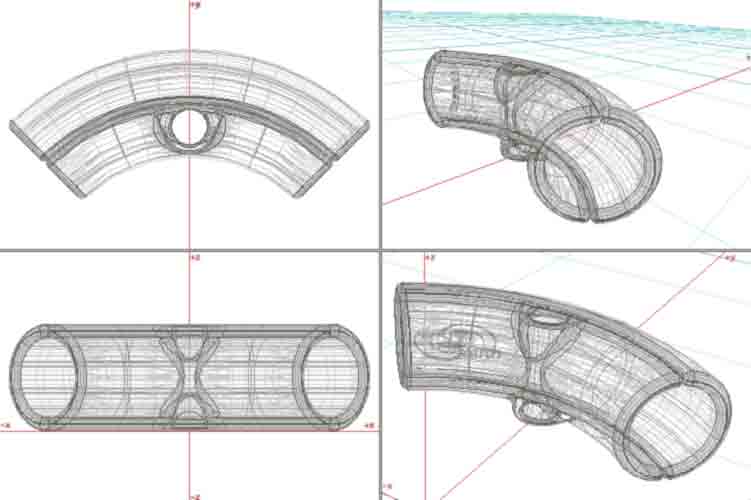

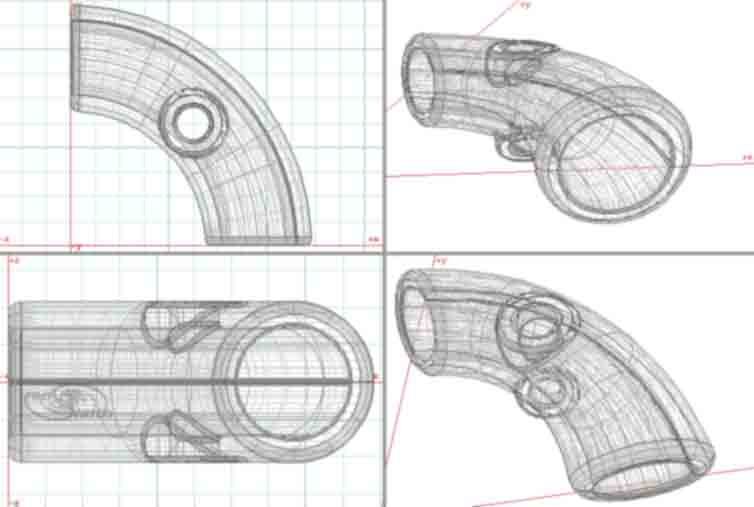

A single donut is visualized

semi-transparently, in the picture above. It can be sand cast in 8 individual

parts, to allow masonry assembly. Parts are further modeled below.

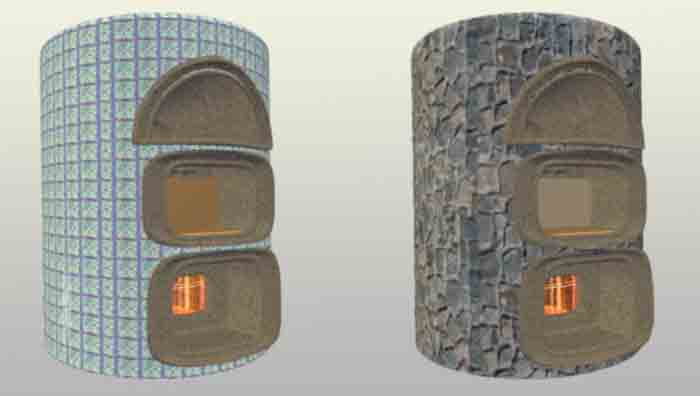

The picture above depicts

vertical seams which may ensure better condensate drainage downward. (Condensate

forms during cold start ups. Liquid should

be channeled

to an appropriate drain.) Yet horizontal seaming depicted below would

accommodate easier installation.

Draft energy is supplied by the fire. Exhaust passes up through the central core. Cooking range and ovens are heated. Next, the exhaust enters the "toroidal flues" at a tangent. An inlet is provided to the top torus from the central flue. Distributed toroidal outlets can be placed advantageously. Domestic hot water heat exchangers are perhaps best placed close to or below floor and can easily circulate within the donuts.The bottom torus may have optional outlets. One option, through an adjacent chimney and the other option through a hypocaust hearth. Advantage is taken from ancient Roman and Korean concepts of heating beneath floor surfaces. The dew point is reached with this large amount of heat exchange. Therefore care is taken to drain all condensate downward, away from living spaces. Liquid should be channeled to an appropriate external drain.

A further feature for consideration is to taper a core in that compressive limitations of refractories may benefit. If all parts lean together concentrically, then gravity will add a small contribution to hold the whole core together. Nevertheless, a cylindrical core can be reinforced with steel wire rings, even as a continuous coil wrapped around the outer surface and covered with a preferred finish.

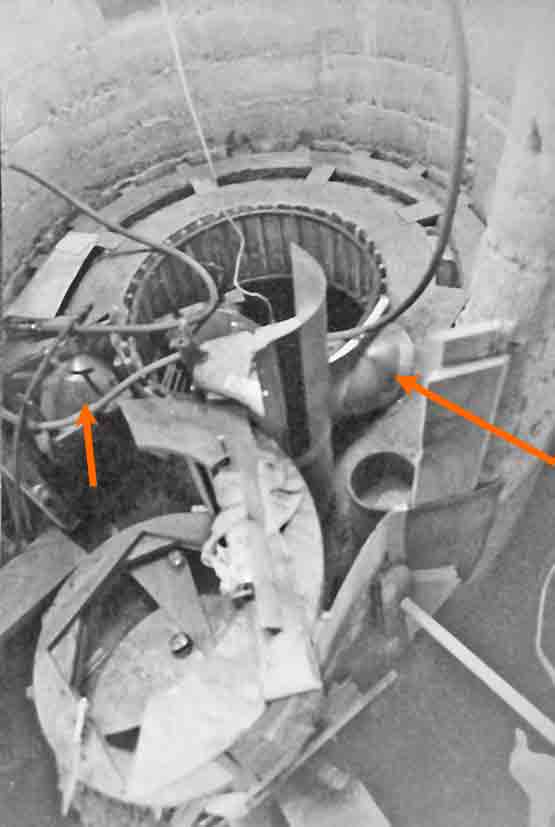

Next Below: A prototype donut core built around 1978. Concentric flues were formed with cast in place donut tiers. The donut molding core utilized an inner-tube from a tractor-tire to form hollow donut flues for a concrete-masonry-heater. The inner-tube was cut to permit some open ring-donuts. The red arrows indicate the inner-tube ends. In future, more photos of this could be posted here.

Vortex Flame Amplifier : Solid Fuel Burner Experimentation - Insulated Firebox Experimentation Monolithic Pour -Tilt upMasonry Heater

Above is a view of my 1978 ferrocement hypocaust floor under construction. Unfortunately i failed to properly seal a barrier to the outdoors, which, the shrews found and tunneled through. I didn't realize that could happen and i therefore had to seal this hypocaust off until I determine to tear up part of the floor and do it right. Ferrocement arches are seen above, along with some short ferrocement joists to the right. Hot exhaust passed above the arches in the valleys. When the exhaust approached the exterior wall, it found access to the underside of the arches and then proceeded to the chimney. The picture below shows scraps of metal bridging between the arches. The metal supported the ferrocement floor poured above it. Also seen is a small plumbing pipe which is still embedded. This pipe had small holes drilled for each valley. Hot water can trickle through and seep downwards through the gravel footing. Hot water is an optional source of heating for the floor and the water table rises near to the surface in this house site, which lead me to think it worth an experiment.

Note: These pages are placed in the public domain and are furnished "as is". The author assumes no responsibility for the use or misuse of the concepts in this series. All authorities should be satisfied first, as might be required, by relevant laws, before any building proceeds.

Searching Synergy .... .... Free Exchange of Ideas

.... Free Exchange of Ideas

Enersearch was incorporated in 1980 but never materialized financially. A synergy of concepts were developed and are reflected in the pages of this series. The synergy continues as a single handed effort of Bo Atkinson, in Maine, USA.

The vertical flues