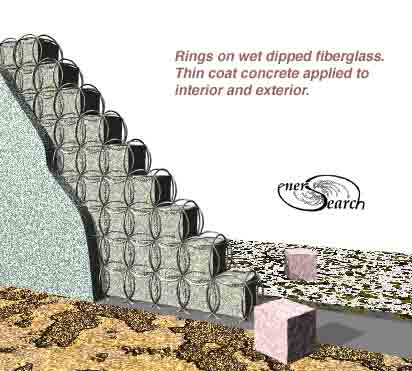

Insulation Products As Internal Forms ForThin-shell Concrete Several Reinforcement Concepts Compared This page will begin to compare manufactured insulation products here intended as internal form work for ferrocement or thin concrete walls and vaulted structure. Fiberglass (rolls or bats) or EPS blocks of nominally cut block sizes would stack one or more abreast to form wall (or vault) insulating mass. Reinforcement on interior and exterior surfaces should link together for strength, by use of reinforcement ties. Relative ease in construction is the primary interest of this page. Desirable engineering data for further comparisons awaits appropriate study and is not unavailable at this writing. (Disclaimer-- These concepts are not advised where construction experimentation is prohibited by law or codes. No claims are made beyond visualization. This is published only as research through free exchange of ideas ). Fiberglass insulation blocks are considered first. Features of interest are -- 1] Building block approach, integrated components easier than traditional FC. 1a) Separate steel frame work is not needed. 1b) Backing not needed/ rebound reduced. 1c) Cellular framing adds structural advantage. 1d) Simpler moist cement curing. 2] Widespread availability and very compact delivery of insulation to job site. 3] Easy curvilinear shaping of walls and vaults. 4] Good insulation values. 5] Can be built by one person alone or with crews. 6] Adaptable to hand tools or power tools. 7] Adaptable to 24/7 PC controlled construction. 8] Potentially low investment required, no form work.Disadvantages for block usage include-- 1] Lower compressive strength than EPS. 2] Needs more effort to achieve good strength plus insulation. 3] More susceptible to water damage.

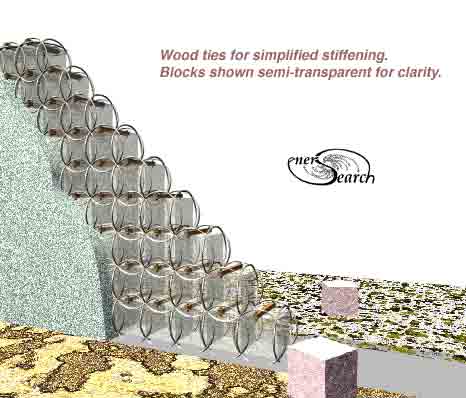

The highly insulating fiberglass block would depend on a stronger tie between interior and exterior walls. EPS, having considerable compressive strength, permits simpler ties between interior and exterior walls. Material stiffness is needed in the ties for fiberglass block. This adds to cost and/or to heat- insulating losses and/or to rot/fire weakening. Wooden ties are pictured next. Ends are pinned or ringed for anchorage.

The ties could be made from a variety of possible materials. Steel wire and synthetic filament are available to form individual or flat spiral rings. Options and the scale of possible applications are many. Homemade - labor intensive through robotic construction come to mind. Free choosing of materials can take advantage of locally available bargain lots.

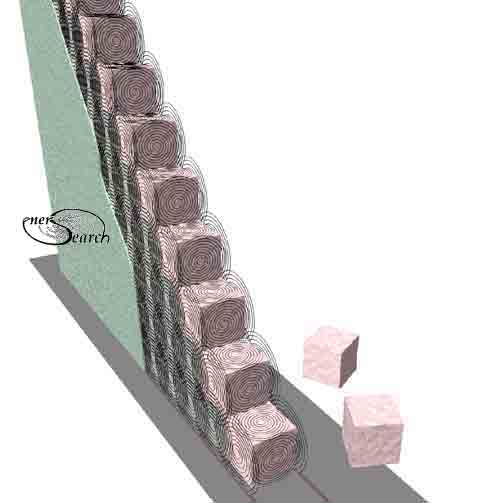

Three directional

(three axes), ring reinforcement may optionally surround insulation block

for structural advantage. In this case an FC or composite ring is proposed

desirable. The picture above represents a thin coat of cement around a

thinner guage of wire. A FC (ferrocement)

ring economizes on the expensive steel part but depends on tooling development

to reduce otherwise prohibitive hand labor. Descriptions of concrete walls

using three axis ring reinforcement can

be seen here (and the original ring-reinforcement here) More on rings

for elements of framing in structures

(click here).Click

here for a page on progressive spirals used in a similar way. Where

labor is not an issue, then hand made FC rings are feasible). More information

on

small

budget, hand intensive

Picture above: Another concept for tieing wall surfaces

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson