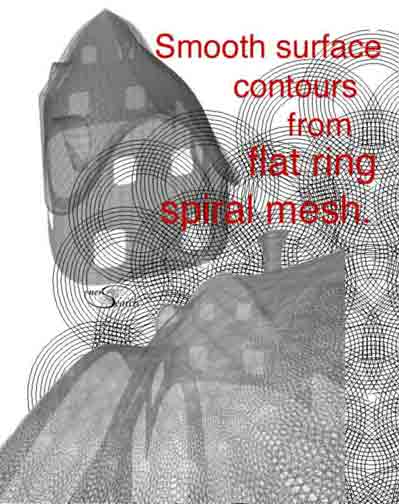

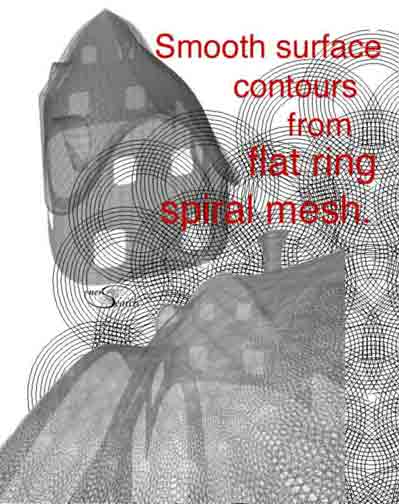

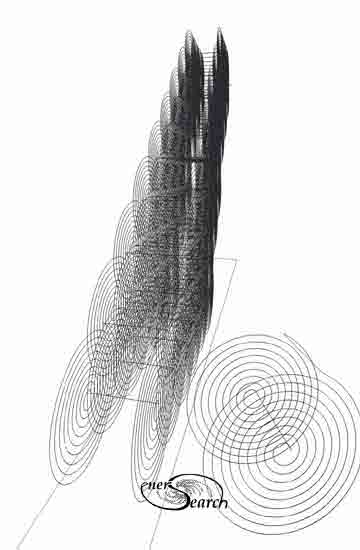

The background graphic on this page studies some spiral patterns

which optimize space coverage for reinforcement . Multiple layers

with patterns overlap to link individual spirals together. Cement or

binder fills spaces between which in effect chains lapping spirals

together. With appropriate tooling, this approach to composite

reinforcement could compete with other reinforcement approaches

in many ways. In situ and pre-manufacture of spiral modules are

both feasible methods under consideration.

The spacing between continuous reinforcement filament can evenly

distribute by progressive spiral layouts. Layers of spiral layouts can

overlap and a filling material like resin, thermo materials or cement.

can bind them in situ, instead of hard bonding mesh grids which kink

on compound curves. The reinforcement filament or wire is potentially

bonded only during formation of product. This could reduce energy

required for initial manufacture and also enhance composite function.

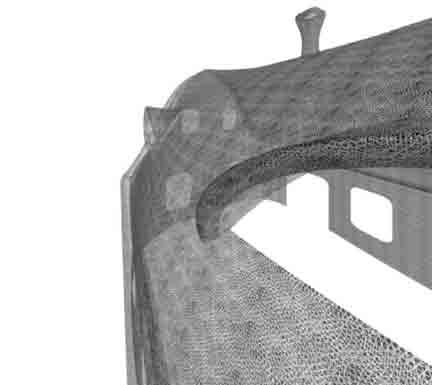

Ordinary mesh or pre bonded grids can limit compound curve forming

of composites. Alternatively, a soft bonded spiral grid is suggested

further below. Compared with established mesh uses this is "thinking outside the box".

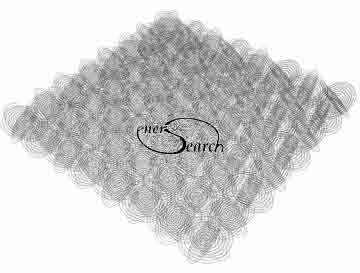

3D Computer model is rendered with spiral mesh map

to suggest ferro-cement or fiber cement application in

house construction. Below are more examples of spiral

mesh configurations and links to other spiral reinforcement concepts.

The construction of composite skins has been mentioned.

Now some ideas for cellular comparmentalizing of walls will follow.

Cellular formations offer lighter structure, insulating qualities and

some potential for trussing. The next below illustrates a spiral

form of truss where the compressive strength of cement ties the

two thin walls together with some measurable truss like effect.

(Click here for a page on similar wll building)

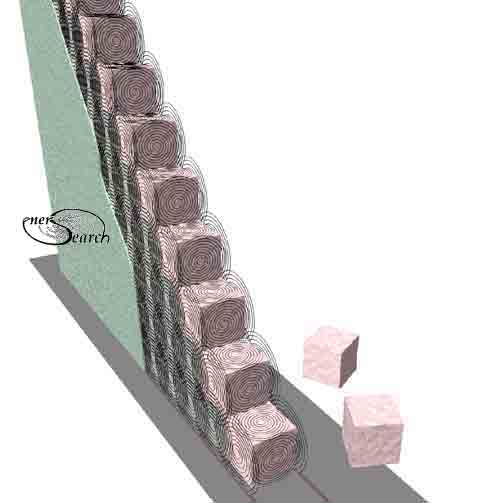

Next picture below shows one possibility for tieing spiral units together.

Next picture below shows a three axial alignment of spirals.

Multiple layers nested togetherlike egg crates offers a 3D grid effect.

Spirals can intertwine this way, tri axially. If a machine were to

intertwine spiral wires or filaments, small beads of adhesive

could hold the configuration for use in a molding process.

This brings up the point that some applications could benefit

from bracing any of the spiral units with cheaper strand materials,

where a prefabricated spiral was preferred over an on- site

or in place winding of spirals.

Too little is known about actual test comparisons between traditional reinforcement, flat spiral loops and individual "O" rings. Rings appear to have interesting test possibilities. As a low budget single handed developer, I have very little opportunity to test the many ideas presented in these www pages. The testing cannot keep up with my my conceptual exploration.

Note: These pages are placed in the public domain and are furnished "as is". The author assumes no responsibility for the use or misuse of the concepts in this series. All authorities should be satisfied first, as might be required, by relevant laws, before any building proceeds.

Searching Synergy .... .... Free Exchange of Ideas

.... Free Exchange of Ideas

Email comments welcome ~~~~~~~ boa1@pivot.net

Tel : 207 342 5796 . . . (Maine)