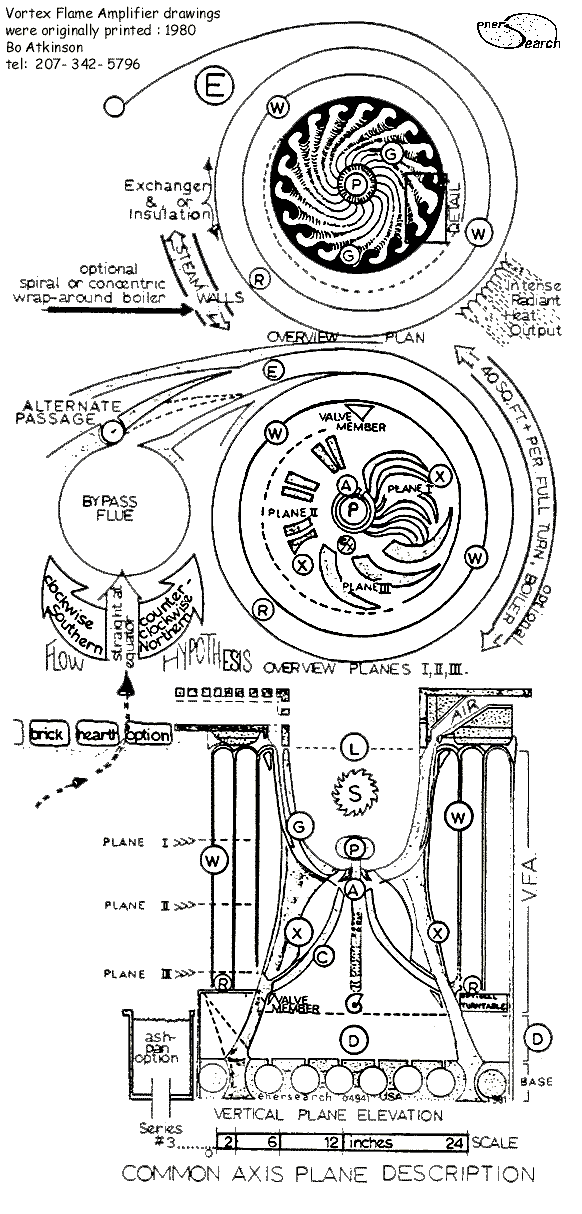

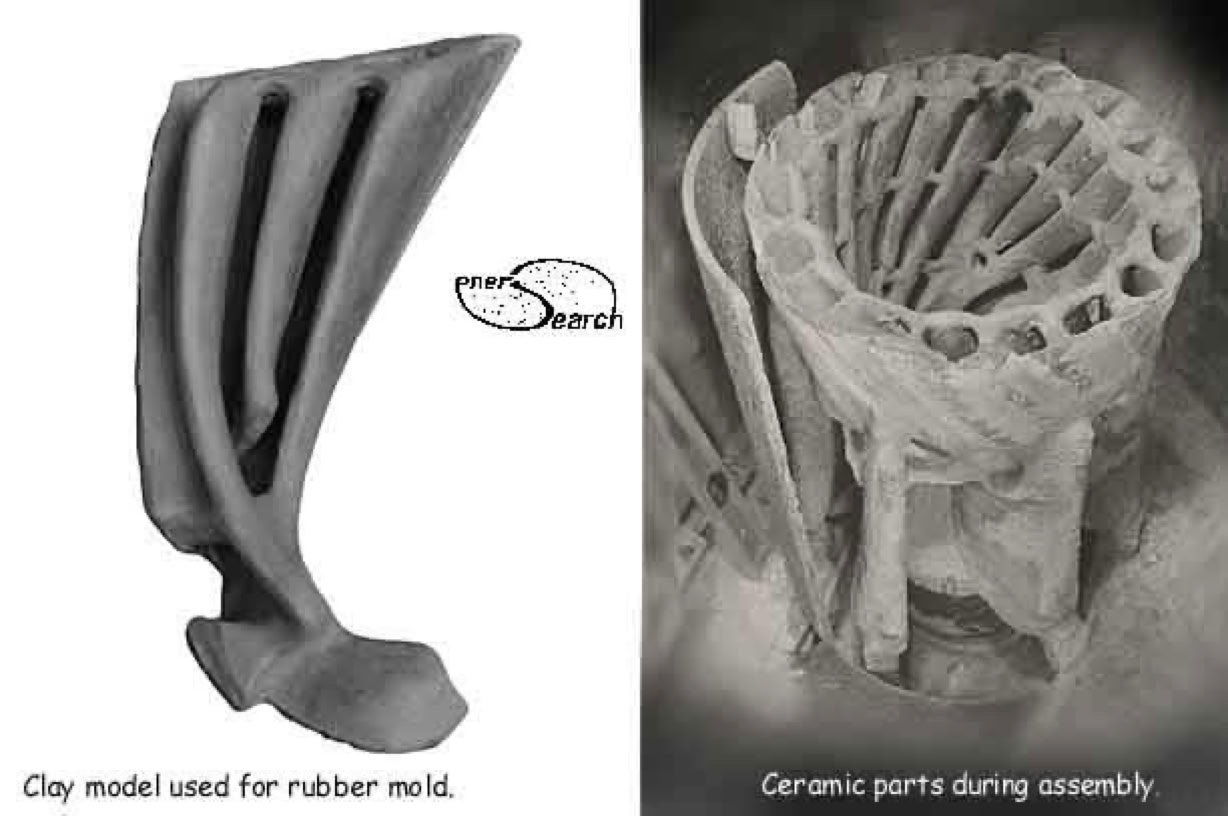

These are the graphic plans outlining research completed1981. Vortex geometries were studied for high temperature refractory construction. A small scale model was built and tested. In brief the essential combustor design addresses the problems of burning solid fuels for many diverse applications. Ceramic castable cements and ramming mixes were chosen because of their adaptability to form and function. While these materials represent advances in technology, they do lack meaningful and desirable tensile strength. Curved surfaces get the most out of the available refractory strength which happens to be almost compressive-only in nature. Thermal regeneration conserves the initial combustion heat for maximizing the burn temperature. This is accomplished by high heat storage and radiant reflection inward to the area of initial combustion.

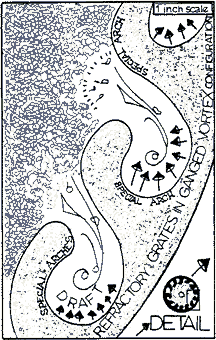

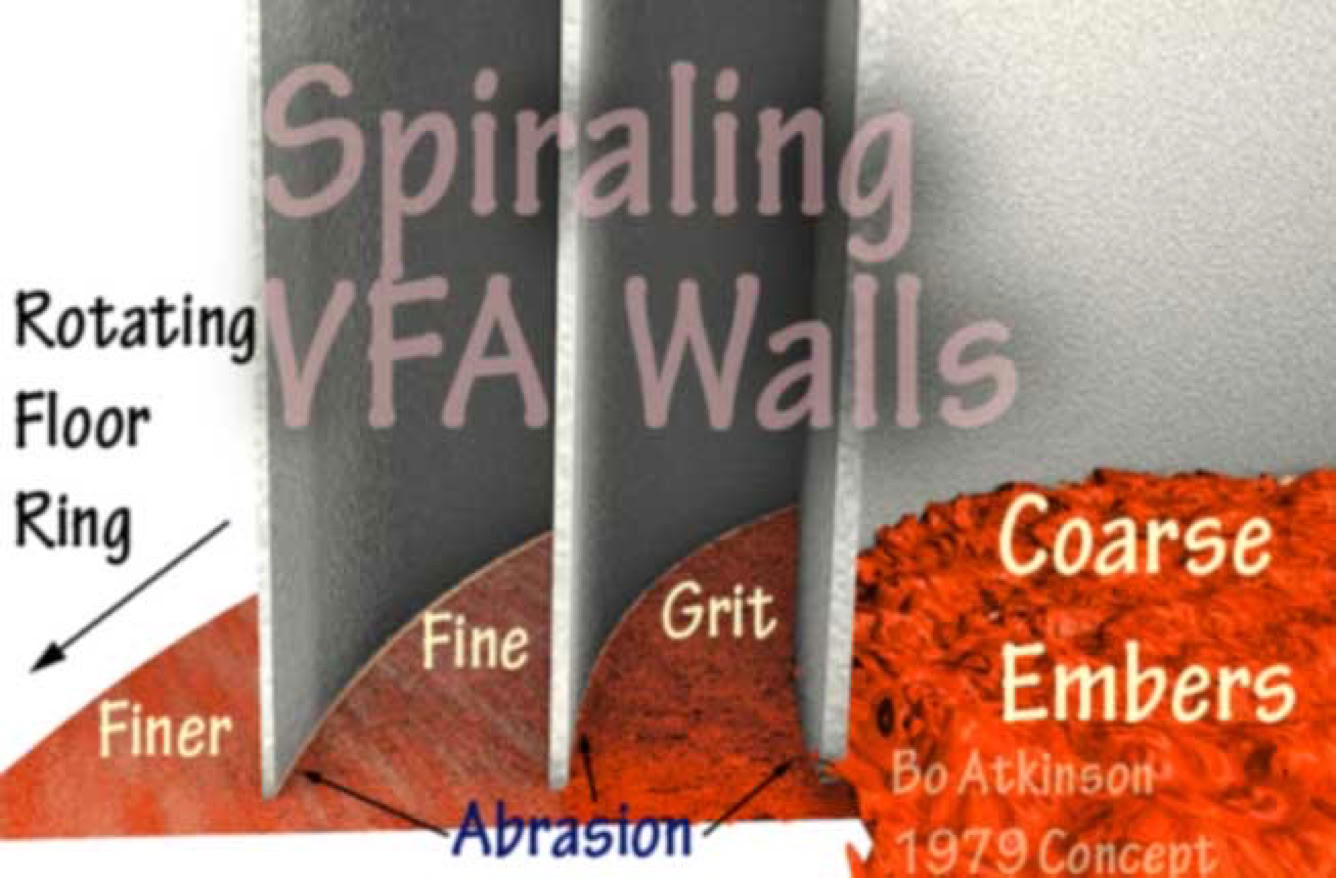

It was reasoned that this burner could work with any solid fuel from coal to incineration. At point (R) in the illustration, it is suggested that an experimental, turning surface would fully circle the base. The turning plate-like surface would turn close to the spiral walls (R). This action, it was postulated, could force ash particles to scrape against the spiral walls (W). This scraping would result in a contiguous, slow sweeping of the ash outwards from center. Because the process can be run refractory-hot, it was reasoned that appropriate ingredients could be added to manufacture cement on a micro scale. In effect a continuous kiln range of temperature could be maintained while dump-feeding fuel and process ingredients from the top, on a continuous basis. Yet much larger scale operation might be feasible also. With appropriate refractory materials, the turning disk and stationary spiral walls could also function as a high temperature grinder.

I had avidly read books on older traditional cupola furnaces and adopted some of the elements, as should be evident. I simply did not have funds.

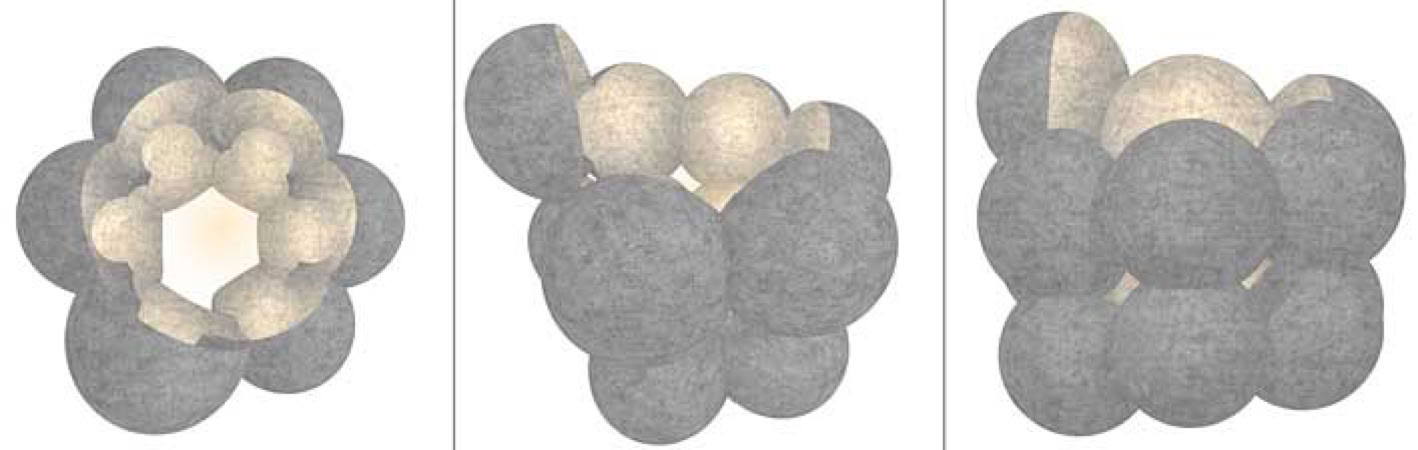

Above: stages from clay modeling to finished ceramic prototype assembly. The refractory castables here used are mixtures of Fondu cement paste by Lonestar Mfg. and the two aggregates were 1) corundum for the grate portion, and 2) potters grog, used for the curved walls. Castable refractories are intended for much thicker applications. I worked with very little money and could barely buy these. I tried some other designs, (not shown) in the succeeding years, especially since i could not afford to implement all the VFA features.

One objective with my VFA research, was to make the most out of solid fuels. Could a useful byproduct be made at the same time, as say heating, (at a decentralized, low cost installation). A new, decentralized form of co-generation might include micro scale cement manufacture. How could one get these advantages, easily manufactured, today, in a small decentralized- off grid burner system? Once had, the user could get the best burn out of what is locally available, especially waste products which inherently need optimal combustion. Yet at the same time have complete, easily maintained, minimal maintenance costs. Self cleaning, continuous operation, combined with micro-manufacturing capability.

The diagram above illustrates the claim, that the spiraling VFA walls could provide a fixed-grinder-surface. With appropriate rollers, isolated from heat, below the VFA, a refractory ring could continuously turn during the burn period. Therefore the embers would tend to be scraped against the spiraling walls. An experiment was considered to see if appropriate, silica-bearing solid waste, such as rice hulls, could be combined with lime and other minerals, in order to manufacture cement.

My concept was to compete with currently huge industrial mills like the reference picture found on-line. I was too preoccupied with sustaining my own life to develop my grinder-mill model.

My built model here was in fact adapted primarily to heat space and water with cord wood. It was encased in insulation and had various "wood chambers" fitted above, to feed even 8 ft long sticks of wood. (A few pictures of that effort appear further below). Too much liberty was taken with heavy pieces of wood which fell too hard during high fire. It lasted some years while the grate portion was gradually pounded away. The spiraling walls (W) remained longer, offering an extended high temperature zone for combustion.

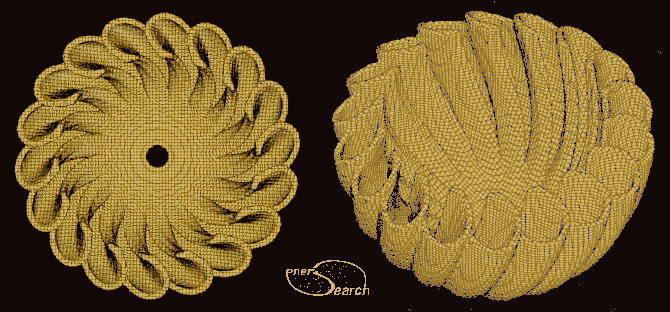

This first enersearch research project was named the VFA for "vortex flame amplifier". The CAD model (at the top of this page) was generated using a 3d modeling software, (formZ) and a geometric form known as metaball. A small report was produced and published in 1981. Further development of this research was suspended, primarily due to my single handed, under-funded approach. I increasing found myself heading into self-sufficency, as a life style, accentuated with occasional small construction contracting.

In concept, this burner should fit diverse solid fuel burning needs. Yet my budgets was was extremely small, (as creatives suffer for their art). My experimental installation was fitted with a gravity-fed chamber above the VFA .Further below follow some brief details concerning the experimental, fuel loading chambers. Both the earlier VFA and the chambers were hand made with lower costing materials. The VFA was not sufficiently fused in the refractory firing, before time constraints forced me to use 'oversized' logs, (too heavy and consequently damaging). My wife and i found few and occasional jobs, to live on, (but at very low income on average). While winter-house-heating compelled hard use of the experimental VFA. The chamber, was largely ferrocement with customized vermiculite mixes for insulation. Insulation intended to conserve high heat i the burn area. The ferrocement proved porous and allowed chamber fumes to leak into our house-- Enough to eventually abandon the experiment.

After needing to abandon the 'thin-walled' structures of the VFA, i devised another 3d form with less delicacy, for simplified wood burning. I was still interested in gravity fed bottom burning. Above is the mold made with wire wound tire-inner-tube. It is seen above coated with with wet clay solution to act as a mold release. (It appears in upside down position).

Lacking a good scanner for 35mm negatives of long ago, fa 3d model rendering is offered instead. The point being that a spiraling-down-draft is induced by the burner-walls. (Naturally the intake and outlet need further detailing. The original, built test model worked with a chimney fan, and the test fans never lasted, so that the finally, plainly insulated firebox proved most practical for home furnaces and wood or log burning in general.