Following is an older page concerning 3D Ringforcment. To see the primary Ringforcement page, click here.

3D rings for reinforcment are a radical approach to:

-minimize material consumption and tooling

-optimize reinforcement of complex shapes

- achieve tensile integrity throughout thick structure

-link compressive cells, (of composite mediums like concrete).

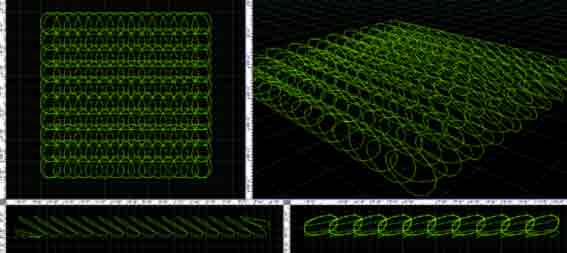

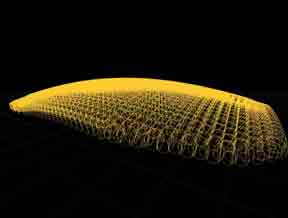

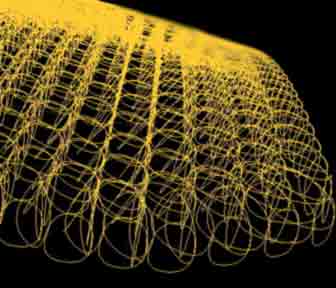

Following are all CAD models of 3D ring reinforcing meshes of adjustable proportions. Pictures are blurred for speedy download over the www.The usefulness of 3Dring reinforcement is the truss like quality which spans across more than one direction and the simplified effort required generally.

Pictured above are 10 helices of 10 turns each, raised at an angle to span 3 dimensions. While ringed reinforcement ties inner and outer surfaces together, additional long wires or bars may be fed through the rings and therefore provide tensile strength along exterior surfaces. This is believed to complete the truss effect, for each path the bars are inserted. To see this illustrated, click here.

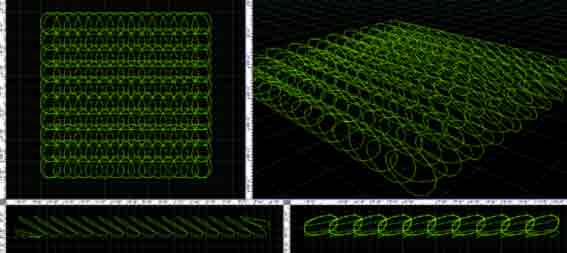

Next above is a model of a four turn helix which has been bent to fit around a specially tapering cube, (which has six faces). The helix is presented here in hope of clarity, but four individual rings might serve equally well. It is proposed that 4 rings positioned and stabilized like this may serve as a module useful in construction and manufacture generally. Proportions may be suited to specific needs. The quantity of rings might also vary and conform to other polyhedra like hexagons, tetrahedrons, etc

.

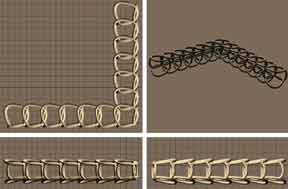

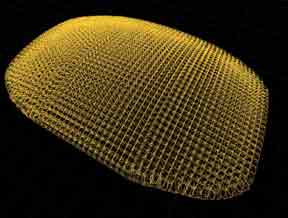

In the tan colors

above is a model of similar rings nested to demonstrate the principle of nesting

in two axial directions. The tan rings are thick which suggest manufacture of

fiberglass rebar or other composites, even ferro cement. A layer of cement on

rings would strengthen them where a low density filler material is used. Following

are other nesting examples.

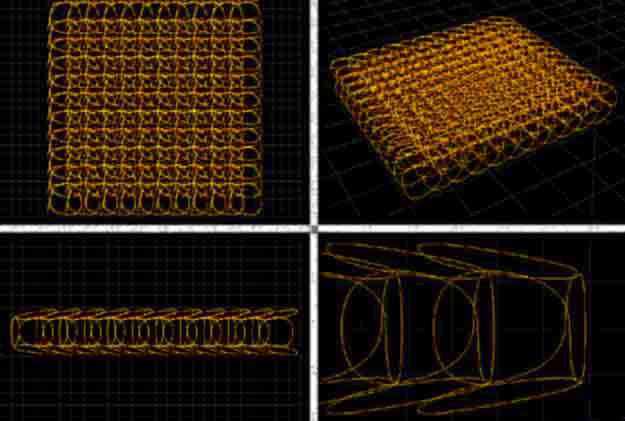

In a square matrix

above, the modules have been nested and arranged to overlap. Nesting ability

of this module is a key feaure which aids practical construction. The nesting

achieves wanted overlap and enmeshing of rings (which imparts continuous tensile

reinforcement). The nesting is a little like a paper cup, except that special

tapering is used to taper in two axial directions. _

_

Above are two pictures showing how the ring units might be arranged for a vault roof. The idea is that while the lightweight concrete is being poured on the roof form, the ringed units could be placed into the pour. These ringed units would have been prefabricated using a material with good tensile strength. Thin steel bar or wire could be wound and then tied, crimped, hooked or otherwise secured. Fiberglass other composite or woven ring units could alternatively be made.

The first link is another 3D reinforcement framework which "nests together" forming a chain linkage after permeated with cement. It is postulated that normal shrinkage cracking is better handled. Such frameworks benefit cold joint or slowly progressive building because moist curing is more easily assured. (Not having large frameworks to interfere with plastic sheet covers). It also hold potential for future cement related power tools

.More on 3D rings for reinforcement, (instant dome from rings).

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson