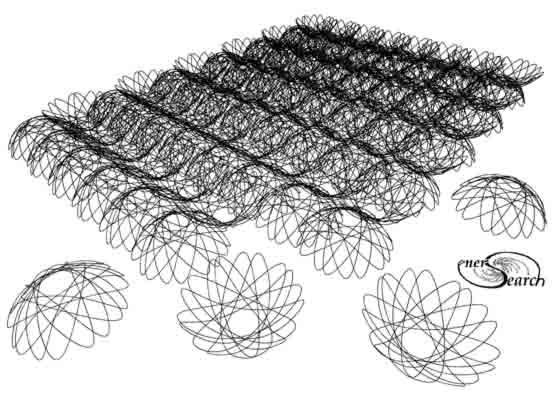

Dome like wire structures instantly form! Hard steel wire, (such as MIG welding wire) will form these dome like structures very easily. A wavy wire lattice can then be simply made, (like egg trays). Intersperse these wire structures in alternating rows, inverting up and down sides. This will overlap neighboring rings of wire and effectively interlock reinforcement properties three dimentionally. This framework is suggested for tieing inside-wall to outside-wall surfaces of cementitious and composite structure. It is a form of "3D mesh". (On this website, the term ringforcement is also introduced and implied).

Picture below: Simply start with hard, springy wire coiled into a manageable diameter. One or two hand spreads is manageable (and this works out to a ratio of perhaps hundreds to one: ring diameter to wire diameter). Hold opposite sides of a wire coil and bend all wires simultaneously over an edge. Bend them all together. Bend them over a rigid, straight edge, (table or chair). The resulting radius of the bend could be similar to a pencilr. Then, having held the wires firmly, let them go. Release them. Latent energy becomes kinetic. the wires spring by themselves into the dome shape.

(You can buy stiff wire at a welding supplier. Buy a small spool for the price of hot lunch. Careful, as soon as you un-tape the spool, the wire will somewhat unravel, from latent energy. The small welding spool might want to unwind to a diameter larger than the one in my picture. I had to reduce the diameter of wires I used. See other links below).

The interesting effect is that each individual bend rotates the next segment. Each segments establishes an independent position relative to adjacent segments. The net effect is a "polar dome framework". By varying the degree of bending and the radius of bending, the height of dome is adjusted. Dish like, low height structure should also prove useful.

Thicker wire and even rods present opportunity for larger "instant domes" elements, "instant dish shapes" , (instant 3D structure). Structural elements or 3D frameworks produce with simple bending motion. Shallower structures like dishes can be patched together to form larger domed or complex curved frameworks.

Variation of 3D structure results from different planes of bending the coil of wire. A single squeeze-bend positioned on the same plane of the wire coil will produce a linear expansion of the coil. (See pictures below). A flat elongated coil is produced with squeeze-bent rings. A dispenser device, (hand powered or machine powered), could feed out continuous linear mesh of variable dimension.The picture below shows the required bending pattern which causes a flat coil to spread in a linear direction. Beginning with a "relaxed" (unsprung) coil of stiff wire, bend as arrows direct. Upon release, all 22 turns will offset the next turn in linear fasion. The same offset can be ge made with a cam or like mechanism, for continuously fed flaat coils. The result is comb like in that the more pointed side can easily feed through adjoiniong coils to create job site meshes, of "endless" length. Plastic filaments could use jobsite thermal anealing to acheive the same essential result.

To observe the effect, simply squeeze the coils as in picture above. (stiff wire must be used). This proves structurally useful in several ways. With one edge more pointed than the other, the coil can be interlinked with other coils. Flat coils naturally have a "comb" property. Two coil can actualy comb through each other to produce hard wired mesh linkage. The linkage is free to hinge and can in fact serve as corner reinforcement for sharp corners.

Repetitive comb links can form hard linked chain meshes . Unlike ordinary meshes, these ring meshes will adjust to compund curviture because they will slide wider or narrower at any point to conform to contours.

Other bending methods also have useful structural potentials. Below are photos of 3D wire dome and sphere. Very small sizes can be machine produced. Initial study suggeasts that these configuations are strong enough to maintain shape in a cement mixer. Used as a reinforcing aggregate, ring reinforcement is most easily implemented, given adequate machine development.

The first link is another 3D reinforcement framework which "nests together" forming a chain linkage after permeated with cement. It is postulated that normal shrinkage cracking is better handled. Such frameworks benefit cold joint or slowly progressive building because moist curing is more easily assured. (Not having large frameworks to interfere with plastic sheet covers). It also holds potential for future cement related power tools

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson