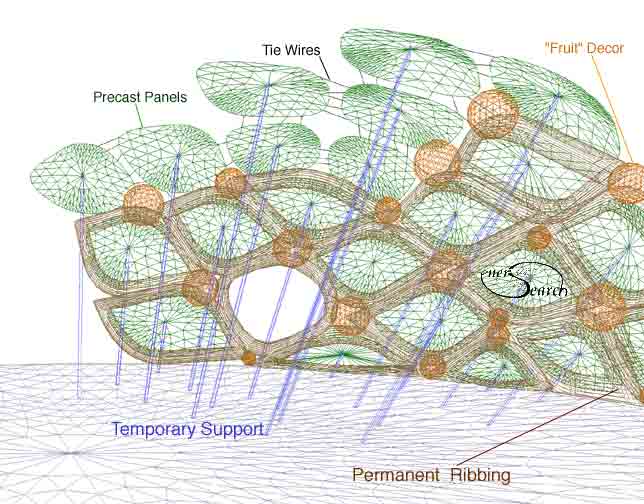

This is meant to simplify house-sized concrete-sculptural form work, (for one worker alone or a several person crew).

Curved tiles formed on a mold* using sticky sand parting agent. Solar curing

for 2 days, then tie panels together while "balancing" on poles. Poles

are also wired to panels and to floor. (Precision mapping and cuts can save

time on site. The wiring leaves plenty of margin for adjustments.) The wired

panels are added a few at a time. "Mortar" together in place, using

additional semi-precast frame sections, (wiring to panel wires). The precast

surfaces become most of the interior finish, reducing overhead muddy toil. Another

advantage of this method is pre-curing much or most of the surface. Pre-curing

reduces difficulties while helping with quality control.

*Molds could be made from cold rolled wires welded with curvature. In this case several variable panels are under study to produce the panels here illustrated. Another option is to use traditional sand molding for panels. A third option is to use a digitizer to define mold precisely with the greatest ease. The workman loves to simplify measuring!

nstant rustic finish quality might be possible. Efficient work production with high customization. Customized coloring and textures can be incorporated through "earth molding". (Click to see long description of Bo's approach to earth molding).

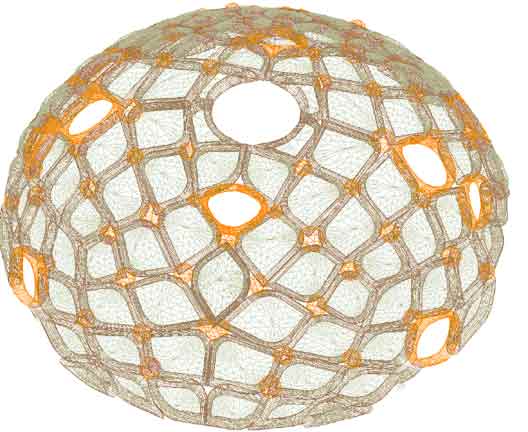

The images are based on a 3D CAD model which contains all necessary measurements. The overall dome design is an adaption of icosa geometry. Icosa tessellated and curved into an arbor shape. Other tile shaping is also under study. The frames represent branches. The panels represent leaves and would have better leafy texture than illustrated above. Click here to see a shell dome concept which can be built with similar methods.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson