This page, first posted April 2020. [Last edit: December 2021]

Rustic Geothermal Concepts For Cold Winters

Based on some years of geothermal experimentation, I am summarizing my observations of large radiator sizes with less-heated water, as compared with the typical small pipe, (or electrical wire), radiant heat floor designs. It is known that one-sage heat pumps in geothermal systems can be most efficient in small applications which include large volumes of heated water like a big heated tank or a large capacity of water in the floor, as outlined here, but one stage heat pumps trade off the higher heat temperatures for economy overall. So it is also a minimal impact approach to heating, (or potentially as cooling too, run in the reverse mode). My commitment was to explore where the outcome led.

Instead of rebuilding our old floor, I adapted my wife's planters to incorporate as radiators, so as not to use up floor space, and to test this principle for it's plant growing effects. Under heat plants with the gentle temperature range was advantageous. This encouraged increasing the drain-pipe radiators for the second year. Theoretically this minimizing approach reduces the industrial impacts on the environment. However, this low cost drain pipe challenges us with a leak under the plants to solve in the future, (and reported here to admit the difficulties of protoyping, along with the rewards). Half way through the third winter, our heatpump needed some refrigerant added, which led to much more education of the finer maintenance details of HVAC, and it's parent refrigeration industry, which is resistant to innovations like mine.. While heat pumps can save energy costs sometimes and to some extent, there certainly was much time taken up by insistently prototyping my specific choices for the system.

Maximizing the size of a geothermal radiators is more readily done within concrete floors or else in a crawl space below a floor. We have already lived in our house for decades and I have not been inspired to tear up the ground floor, for retrofitting. This kind of heating equipment was not commercially available when I searched for it in the 1970s. In the second year, I added some large pipes in a high ceiling space to test the cost of pumping water higher up, which costs does cost a little to pump. I had initially experimented with pipes on top of wooden floors, to reveal all possible issues which has revealed challenges of my low cost cement fixtures. If readers ask for it, I will offer more information and pictures; however for now, this page focuses on sub floor concepts for space heating; and leaves the further research of producing low cost pipe connectors for another day. As far as I know applying for code approvals would be a large task in itself, where do-it-yourselfers are permitted to build their own home heating equipment here in Maine.

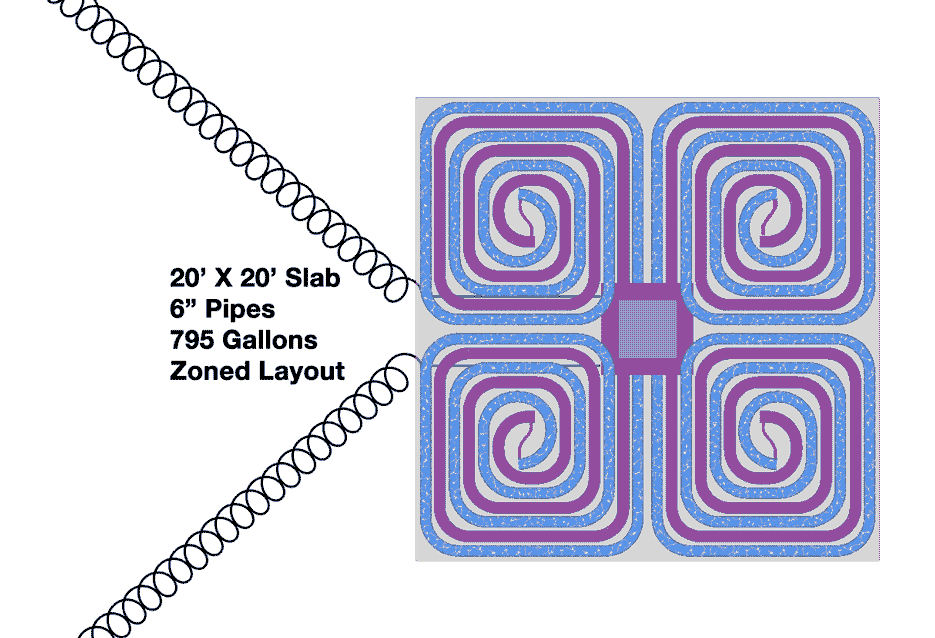

Largely dirt floors or soil underlayment is common in our world and advancing technological design should appreciate the idea of such pipes laid in soil for economy and ecology; if if insisted, appropriate cement mixes could be poured like a slab to incorporate the pipes. Approximate conversions, 6" Inside diameter equals 15 cm, 110 gallons equals 416 liters, 88 galloons equals 333 liters, and 913 feet equals 278 meters, 718 ft equals 218 meters, 10't X10' roughly equals 3m X 3 m.

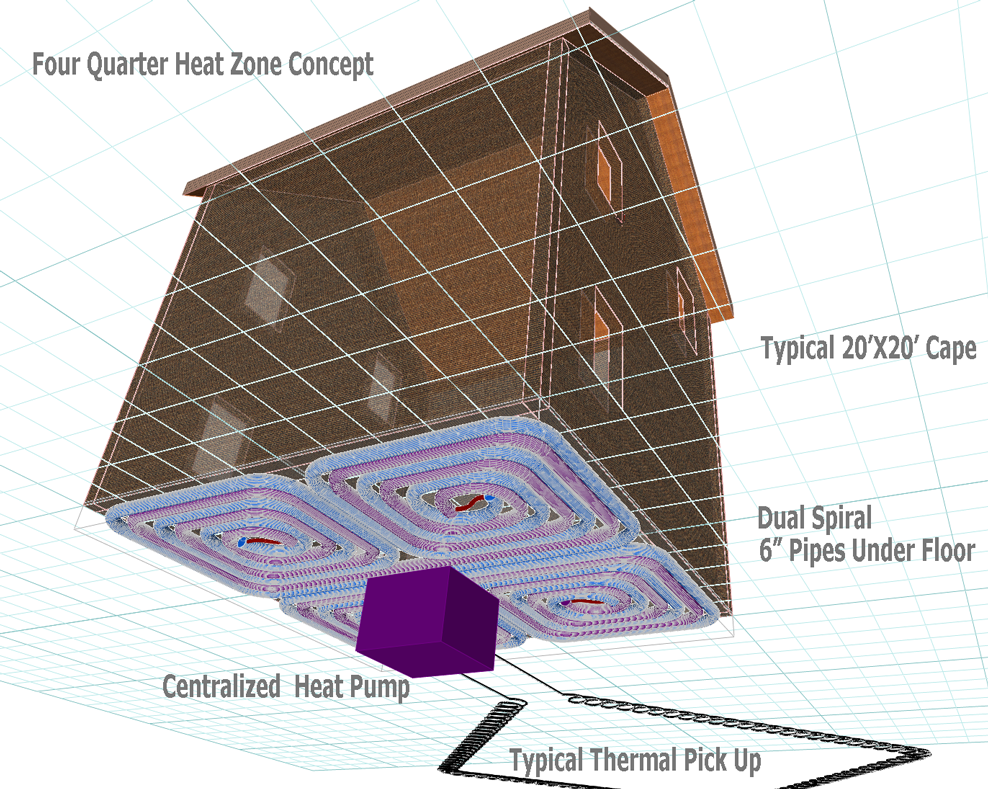

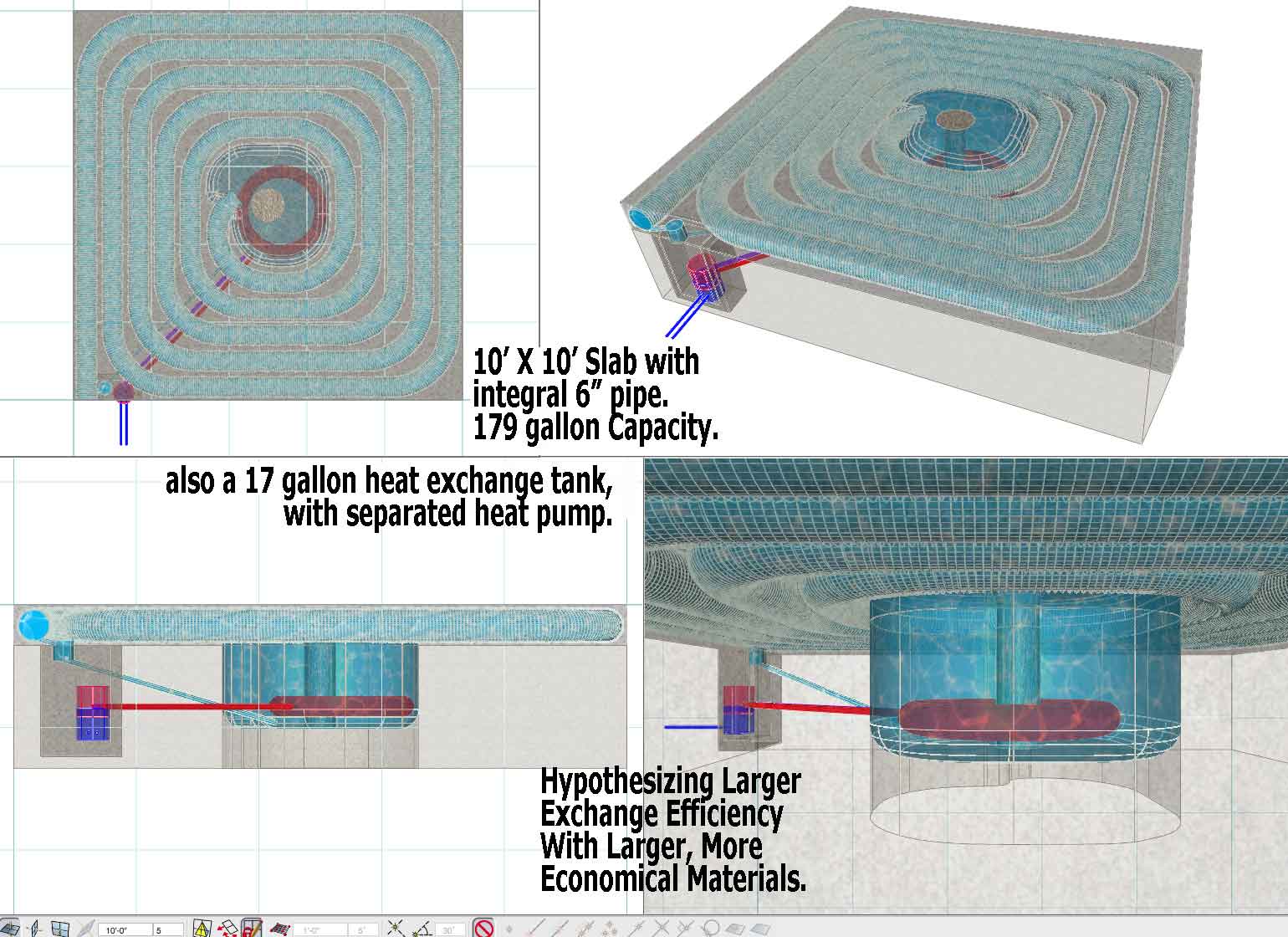

Here are modeling efforts to emphasize the volume of radiant floor heat capacity, in a visual way, and furthermore to estimate the amount of tubing which may fit in a 10 ft X 10 ft space, by laying out two spiral pipe paths, joined at center with smaller pipe. All measurement are approximate and this design effort was to mathematically estimate the possible water capacity for lower geothermal temperatures, in a typical slab.

Larger floor spaces are easier to fit more pipes, which in turn provide more possible heat storage, which provides several advantages. 1.Heat storage guards against power outages. 2. Heat storage conserves on peak-power usage during daytime hours, which helps society moderate wasted infrastructure, and moderates peak hour usage, for the same, obtainable, heating benefits. 3. Embedding large pipe circuits in concrete slabs could conserve on concrete. (The downside is the challenge of new placement methodology and code acceptance, or as an added cost for the pioneering buyers of new systems, and finding able contractors who are willing to master new systems.

My economical experiment featured the expediency of Portland cement, (slightly modified), to seal and waterproof all plumbing connections. The plastic plumbing and drain pipes certainly exhibit a significant difference of expansion and contraction in relation to cement, when temperatures vary. Overdoing the economical thinking, wire clamps were fashioned for these pipes "to clamp onto my pre-cast cement adapter-inserts". At some connections, experiments with short copper pipe pieces were inserted inside plastic tubbing, which embedded cement-tank-walls, (and also embedded inside customized cement plumbing adaptors), proved leaked proof. Cement seals are very expedient money savers, but at this point are still experiments under observation. One must check with building codes before considering these innovations, but rural localities might allow testing new innovations of conservation, such as cement plumbing connectors.

Cement junction-adaptors are very conservation minded, for adapting different sized pipes and tubing, while same size connectors could use standard fittings with sealants. For a Portland cement modifier I used an industrial grade of methocell, (sources may be found on today's web-search-shopping: copy-paste: concrete + methocel + cement). Small measures of these additives hugely improve the cement-cure and bonding, and also improves workability and stickiness, yet innovative mixes should be test before supposing the mix was right. For the larger plumbing-junction-adapters I added PVA fibers to improve crack resistance and 3D-shaping. Meshes and wound wires are conceivably desirable additions, although I was testing the bottom line in my experiments. See this earlier blog-page for my experimental size-adapter methods.

A floor with tubing as a radiator, integrates a large capacity of water heat storage, which can double over as summer house cooling, where the cool night time air can be allowed to cool the floor and the still water inside the tube can store this temperature gradient, in regions with cool nights, that is. Hotter climates with hot nights can also reverse their water heat pump, for cooling the spaces, as reversely radiant floors, so to speak.

Multi circuits of tubing can zone parts of a house to conserve energy costs. Next below is a concept of enlarging a heat pump exchanger inside a tank, to trade a larger size pipe for a possible reduced circulator energy consumption. Coloring of pipes in pictures is primarily to distinguish circuiting options.

This illustrated concept is interesting because drain pipe is cheaper, and it's use significantly conserves resources. Much larger exchanger surface areas consequently need less agitation energy, for the same work of exchanging heat.

When inserting smaller pipes in cement surface junctions, I did notice the that older vintage PE, "black plastic tubing" was difficult to keep leak-proofed against cement on it's outer perimeter, during the cooling down phase of the system where coefficients of expansion differences, between the two material types, do differ and thereby causing a slight amount of leaking. The remedy is to insert a short little copper or stainless pipe inside the plastic to prevent inward shrinking, and to improve resilience of the connection.

My conclusion is that leak proofing is possible with these inserts; and also that in the case of plastic outside of cement connectors, should be clamped with large pipe clamps, where I had initially tried simpler wire twists on the large pipes. In some cases, wire alone was sufficient to clamp the pipe and keep them leak proof, but not in every case, where I remedied the leaks with large pipe clamps. The ferro cement or concrete could be improved over my work by use of a high quality vibrator tool adapted to pipe fitting, which in fact is likely a nonexistent tool, and one which should use possibly ultra sonic vibrations and shaped effectors to address the round shapes of pipes. This was far beyond my meager budgets, but I would be glad to assist others who might like to advance these arts, as time permits.

I am still adding the further possibilities for use of these thin walled drain pipes, as time and the drive to do so permits. However want to report the following right away:

Just days after my first posting of this page, I discovered a leak under my wife's plants. I had already written that when heated, these corrugated drain pipes tend to snake and lengthen due to softening of the plastic, which reaches a point where a small water pressure expands the free-standing, unsecured drain pipe, almost like an accordion. This should prompt others to deal with this factor early in the planning stage.The accordion like drain pipes deserve securing by wire, wood or best of all in sand or cement. Otherwise unsecured sections will surprisingly snake around when hot... Speaking of which, here is another reason to use single stage heat pumps never to reach 54º C, or 130º F, but typically running considerably lower than that extreme.

December 2021: The fate of my geothermal installation was a prematurely dead scroll compressor. The motor runs but there is no pressure readings at all and, (as read on pressure meters), nor do any pipes or the sealed metal jacket of the compressor feel warm or cold after running for a while. Which part has broken I cannot tell. Sadly I could not get the needed specifications for pressure settings, as these are not stamped on the name plate, nor provided by the manufacturer or vendor, and perhaps I let the pressure run too high, as pressure rose on its own some times after long days. One spec I found for the high pressure gauge, posted somewhere on line, was over 400 psi but I kept mine well under that... One tech said you have to run everything lower than the commonly stated ratings, which if true means that efficiency is sadly reduced and running costs are consequently higher than expected. I was hoping that heat pumps were more cost effective, based on the boastful efficiency claims.

This unit is:

Goodman 1.5 Ton 15 SEER R410A

Complete Split System Heat Pump

geocool Series Sticker on unit:

Model WTW024-A

Material Efficiency Prototyping

#Heat Pump

#Floor Heating

#Water to Water

#Geothermal

#Ground Source

#High COP