Pail-Sized Mixer/ Batcher For Continuous Production Of Concrete

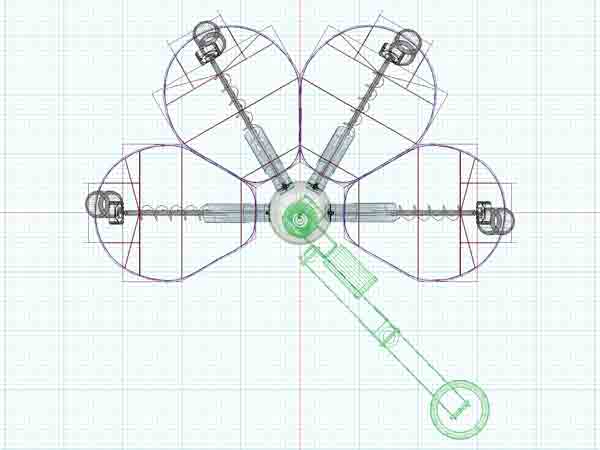

The purpose is to free a concrete man or mason's hand from mixing work. While a person mixes mud at double the cost, automatic tools should reduce costs. A one-man, best seller batcher could be manufactured and probably has not been produced due to manufacturer-sector obsessions with wood tool products.. Consider the stellar investment in power tools for wood working and the near absence of equivalent power tools for small scale stone work. (Small power tools for concrete and varied composite materials are largely custom built). Cementitious trades are held back from competing strongly, due mostly to lack of power tools. Cementitious or bonded stone is many artforms the wider market should discoverThe goal of this page is to encourage introduction of a small scale, portable batcher. A light weight, compact size, semi automatic, dial a mix, high efficiency design , (producible at reasonable cost. Screw feeders turned by gear motors meter the mix components into a common pail at center. The ingredients are regulated by a timer switch which can quickly "dial up" milliseconds of feed time, (and accurately). Each screw feeder is near the bottom of a sheet metal bin.

.

The bins form a semi circle around the mixing pail. Several optional aggregates

along with one bin for cement may feed the pail at center, even while

mixing. Water may be metered similarly, or by old fashioned "measuring

cup".

A nearly automatic pail fill of cement should be possible and is highly

desirable for a small scale operation. A well made bin could keep cement

much longer

than traditional cement bags, (which hungrily absorb atmospheric moisture).

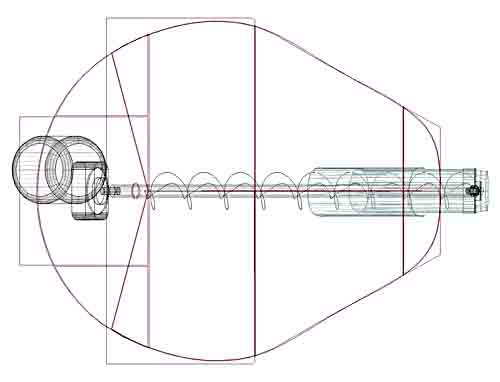

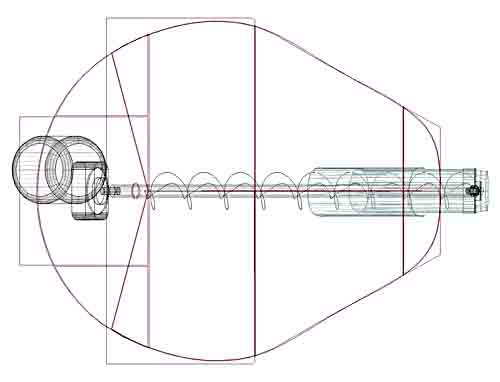

The proposed mixer is a gear motor with impeller which swings or hinges

down into the pail or up and out of the pail. The cork

screw bit or impeller offers thorough mixing with low splatter,

efficiency and less human attendance

needed. Research continues with several sizes of impellers and

buckets and holders. The spiral action has long been sold in a variety of configurations.

Closest to

the vertical

corkscrew

impeller

is

the

bakers

dough

mixer-impeller.

Design variations are possible, all of which efficiently nest together

for batch mixing use or easily come apart for transport,

(even by one person).

The whole

system could fit in a small truck or trailer. Alloy metals

and insitu cement pumping is also under consideration. Below

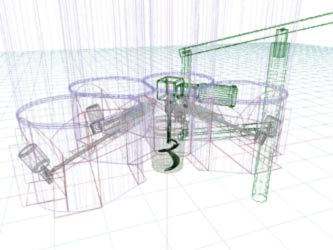

are pictures of the author's humble efforts to prototype

this design. First the pattern was optimized for cutting

all

pieces from

a 4ft X 5ft

sheet of 12

gauge sheet steel. Bids were taken from local shops but the

best deal was to have the straight cuts sheared by vendor

and cut the

curves my

self free

hand.

(Computerized cutting services still a bit expensive locally).

Initial bending was economical by vendor which gave a good

start. Fine bending was finished with car jack, chains

and channel steel,

(melting

snow in background).

Next time, excess bending should be asked for. Over bending

is much easier to correct for low budget prototyping.

Welding went very well with a new MIG welder (Winter 2003). Since then project

has been put on hold. The gearmotors purchased from Surplus

Center proved too weak to initiate screw turning. They have an impressive

surplus

selection but none

just right for this.

Brand new gear motors start at several hundred dollars.

Time ran out and other commitments put batcher progress on hold.

Non profit

research

can go

very slowly.

Since that time a more powerful, brand-new gearmotor

has been purchased. Update will follow when time permits.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson