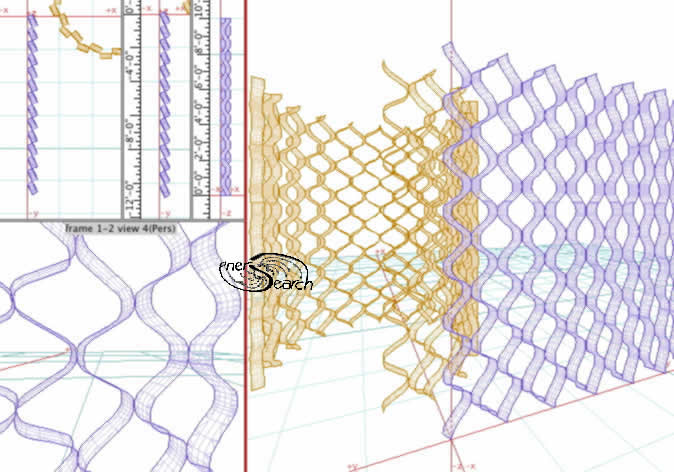

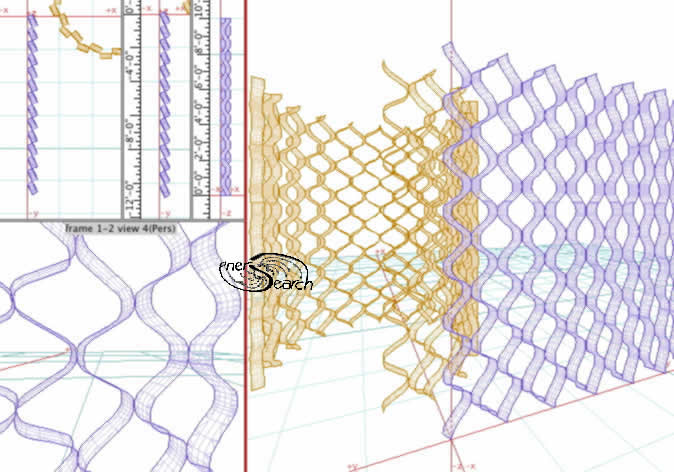

The pictures below should represents material much like "expanded lath", but yet again expanded! The timeless paper cutout idea of making many slits in paper and then "pulling" to open up a 3D structure. My expanding thought is why not take existing expanded mesh lath and slit it like the timeless paper art...

The present picture (July 2003), actually looks more like animal fencing substituting for expanded metal lath. I will add another picture to better show lath expanding lath. Lath expansion is interesting as a means to mass produce 3D sheet material. Expanded structure is further expanded.

The same old hexogonal expansion further extends the 3D matrix. How many iterations make sense? Given existing mass produced mesh sheets, just one expansion is reasonably hand made to explore possibilities. A home experimenter could expand a sheet or two of lath. On industrial scales, more iterations are possible and other material alternatively apply. Further expansions of already expanded sheet further automate the 3D structural building tasks and while adding stability at progressive scales.

Plastic sheet can be treated like paper cutouts. Resultant plastic lath

could be thermo- bonded with flat poly sheet on both sides to form

a new glazing.

The lightweight panel would gain stability from the 3D aspect. Adding sheet

to both sides further stabilizes and also gives a little insulation.

It would seem

to me that a commercial product would interest small builders, if not larger

developers as well. A number of simple or modular panels could be quickly

screwed together with drills, to form quick structures. Much as ply

wood upstepped construction.

Tent like temporary structures or better plastic, stiffer plastic panels, all

are possible.

Mass production advantage of stamping out more iterations of expanded lath, as an additive building method, contrasts subtractive cut out and piece together systems. I am informed that "Large Scale Freeform Fabrication" is a structural approach gaining popularity.

Plastic and metal modular products, both come to mind. Uses of either in composite

structure also are suggested. For example ferrocement methods could take

advantage of quickly erected structure. Spraying cement onto such panels

quickly produces

rigid structures. Considerable 3D stability would be mass produced and

made available to builders off the shelf, saving considerable hand

labor.

Additional illustrations will be added as time permits. These concepts are

placed in the The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages. All relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson. Others are encouraged to add there ideas to

this

idea.

Links on

the www are invited.

Too little is known about actual test comparisons between traditional reinforcement, flat spiral loops and individual "O" rings. Rings appear to have interesting test possibilities. As a low budget single handed developer, I have very little opportunity to test the many ideas presented in these www pages. The testing cannot keep up with my my conceptual exploration.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson