Update, June 2001... The first

two pictures are of a quickly made pail sprayer, ( for a "5 gallon"

or "20 litre" pail). The first picture shows the lid of the pail

to which a hose, a valve, a funnel and brackets have been fastened.

The next picture

shows the underside of the lid, revealing the simplicity of screw gun

fasteners and the simple

90 degree elbow pipe fitting which directs the spray air. The lid is

held

on to the pail using a simple rubber strap. Moderate slump cement effectively

can be sprayed by balancing the filled pail rig on one's knee and opening

valve while "pouring" the cement.

A summary of experiments will be reported here eventually. Pictures below

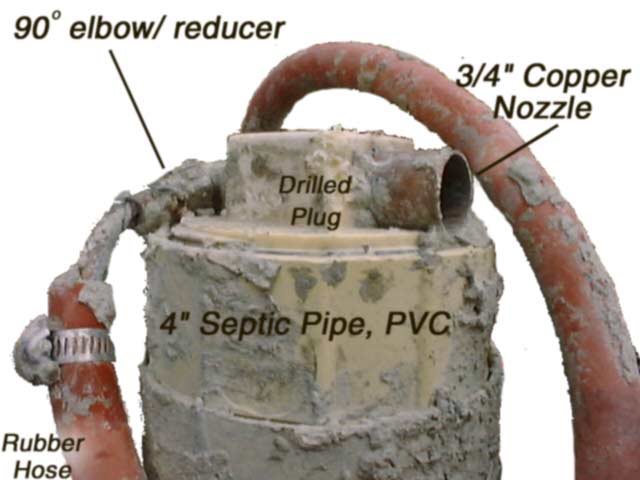

are of an earlier, smaller sprayer used for more delicate cement spraying.

Below is a close up looking down

the "barrel".

The 3/4" (2cm), I.D. copper tube has been cut at center with

an oval hole to allow cement to fall into barrel. At the far end

the small orifice has been forced into the 3/4" tube, itself

wrapped with odd bits of tubing and tape to secure in place. Although

i never got around to it, i was going to place a small "air-bladder" (balloon)

to check the cement when air is not triggered into use. An elegant way would

have been to connect the air -bladder through

small orifice to the same air line. Then, when the trigger is pulled,

the air bladder deflates, allowing cement to fall onto airstream.

(In the picture below, the rubber tube needs securing away from

nozzle, this is a quickly written/ photographed page).